Likarolo tsa boleng bo holimo tse entsoeng ka mokhoa o nepahetseng

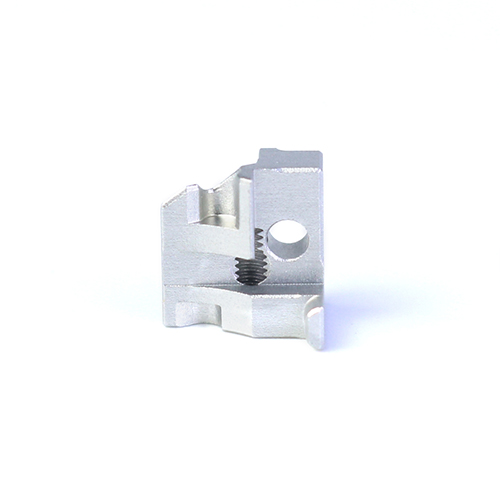

Tlhaloso ea Sehlahisoa

Lefats'eng la tlhahiso, ts'ebeletso e nepahetseng ea likarolo tsa ho sila ea CNC e bapala karolo ea bohlokoa ho faneng ka lisebelisoa tsa boleng bo holimo, tse entsoeng ka tloaelo bakeng sa liindasteri tse fapaneng. Ho sa tsotellehe hore na u sebakeng sa lifofane, likoloi, lisebelisoa tsa elektroniki, kapa tsa bongaka, CNC milling e netefatsa ho nepahala ho ke keng ha bapisoa, ho sebetsa hantle, le ho tenyetseha ha merero ea hau.

Fumana hore na ke hobaneng ha litšebeletso tsa rona tsa ho roala likarolo tsa CNC e le khetho e holimo bakeng sa bareki ba batlang bokhabane ho machining le hore na re ka etsa hore mehopolo ea hau e phele ka likarolo tse entsoeng ka nepo.

Precision CNC Milling ke Eng?

CNC milling (Computer Numerical Control milling) ke ts'ebetso ea tlhahiso e sa thekeseleng moo lisebelisoa tsa ho itšeha ka rotary li tlosang thepa ho tsoa ho workpiece ho etsa libopeho le likarolo tse nepahetseng. Ho fapana le mekhoa e tloaelehileng, CNC milling e fana ka ho nepahala ho ikhethang, ho pheta-pheta, le bokhoni ba ho sebetsana le li-geometri tse rarahaneng.

Ts'ebeletso ea rona ea ho sila e nepahetseng ea CNC e sebetsa ka ho khetheha ho theheng likarolo tse nang le mamello e thata, meralo e rarahaneng, le mefuta e mengata ea lisebelisoa, ho netefatsa hore litlhoko tsa hau tse ikhethileng li fihlelleha ka boleng bo ke keng ba lekanngoa.

Melemo ea Ts'ebeletso ea Rōna ea Likarolo tsa ho Milling tsa Precision CNC

1.Ho nepahala ho sa Bapiseng

Mechini ea rona ea morao-rao ea CNC ea ho sila e fana ka likarolo tse nang le mamello e thata joalo ka ± 0.01mm, e netefatsa ho nepahala esita le meralo e rarahaneng ka ho fetisisa.

Khetho ea 2.Wide Material

Re sila lisebelisoa tse fapaneng, ho kenyeletsoa aluminium, tšepe e sa hloekang, titanium, koporo, polasetiki le tse ling. Boitsebiso bo bong le bo bong bo khethiloe ka hloko ho latela litlhaloso tsa morero oa hau.

3.Li-Geometri tse rarahaneng

Ho tloha libakeng tse bonolo tse bataletseng ho isa ho libopeho tse rarahaneng tsa 3D, bokhoni ba rona ba ho sila ba CNC bo ka sebetsana le meralo e thata ka ho fetisisa habonolo.

4.Tharollo e sebetsang hantle ka litšenyehelo

Ka ho sebelisa theknoloji e tsoetseng pele, re ntlafatsa ts'ebetso ea tlhahiso ho fokotsa litšila le ho fokotsa litšenyehelo tsa tlhahiso ntle le ho senya boleng.

5.Custom Finishes

Ntlafatsa ho tšoarella le botle ba likarolo tsa hau ka lisebelisoa tse kang anodizing, polishing, powder coating, kapa sandblasting.

6.Linako tsa ho Fetola ka Potlako

Mekhoa ea rona ea tlhahiso e sebetsang e netefatsa hore likarolo tsa hau li fanoa ka nako, nako le nako, ebang ke bakeng sa prototyping kapa tlhahiso e kholo.

Likopo tsa Likarolo tsa ho Hlōla tsa Precision CNC

Litšebeletso tsa rona tsa ho sila tsa CNC li sebetsana le mefuta e mengata ea liindasteri le lits'ebetso, ho kenyelletsa:

1.Likarolo tsa Sefofane

Likarolo tse bobebe empa tse matla joalo ka masakaneng, matlo le likarolo tsa meralo.

2.Likarolo tsa Likoloi

Likarolo tse ikhethileng joalo ka likarolo tsa enjine, likarolo tsa phetisetso, le litsamaiso tse emisitsoeng.

3.Medical Devices

Lisebelisoa tsa ho buoa tse nepahetseng haholo, lisebelisoa tse kenngoeng, le lisebelisoa tsa tlhahlobo.

4.Elektronike

Libaka tse tloahelehileng, licheso tsa mocheso, le likhokahano tsa lisebelisoa tsa elektroniki.

5.Lisebelisoa tsa Indasteri

Likarolo tse hahiloeng ka mokhoa o nepahetseng joalo ka likere, li-clamp le li-brackets tse ntseng li hola.

6.Liroboto

Likarolo tsa matsoho a liroboto, manonyeletso a nepahetseng, le litsamaiso tsa othomathike.

Kamoo Mokhoa oa Rōna o Sebetsang Kateng

1.Consultation & Design Review

Abelana le rona lifaele tsa hau tsa moralo kapa litlhaloso. Baenjineri ba rona ba tla li hlahloba bakeng sa ho etsoa le ho fana ka maikutlo a ntlafatso ha ho hlokahala.

2.Khetho ea Lintho

Khetha ho tsoa mefuteng e fapaneng ea lisebelisoa tse loketseng ts'ebeliso ea hau. Re fana ka likhothaletso tsa litsebi ho netefatsa liphetho tse ntle.

3.Precision Milling

Mechini ea rona ea CNC e qala ts'ebetso ea tlhahiso, e fana ka likarolo ka nepo le botsitso bo ikhethang.

4.Ho Qetella ka Bokaholimo

Iketsetse likarolo tsa hau ka likhakanyo tse matlafatsang ho tšoarella, ponahalo le ts'ebetso.

5.Tlhahlobo ea Boleng

Karolo e 'ngoe le e' ngoe e hlahlojoa ka hloko bakeng sa ho nepahala ha boholo, boleng ba thepa le ho qeta bokaholimo.

6.Ho tsamaisa ka sekepe

Hang ha e se e amohetsoe, likarolo tsa hau li kenngoa ka mokhoa o sireletsehileng 'me li romelloa sebakeng sa hau.

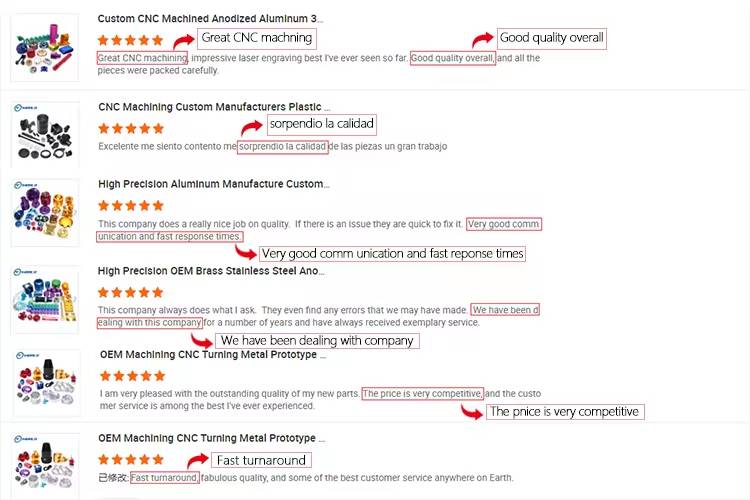

Selekane le Rona bakeng sa Litlhoko tsa Hao tsa ho Milling tsa CNC

Ha ho tluoa ts'ebeletso e nepahetseng ea likarolo tsa ho sila tsa CNC, boitlamo ba rona ba bokhabane bo re khetholla. Ka ho shebana le boleng, katleho, le khotsofalo ea bareki, re fana ka likarolo tse sa fihlelleng feela empa li feta tebello ea hau.

P: Ke likhetho life tsa ho itlhophisa tse fumanehang bakeng sa likarolo tse kolobisitsoeng hantle?

A: Re fana ka litharollo tseo u ka li khethang ka botlalo, ho kenyelletsa:

Khetho ea thepa: Mefuta e mengata ea litšepe le polasetiki.

Lijeometri tse rarahaneng: E khona ho hlahisa meralo e rarahaneng.

Mamello: Ho fumana mamello e tiileng ea ± 0.01mm kapa ho feta.

Liqeto tse holimo: Likhetho tse kang anodizing, plating, polishing le sandblasting.

Likarolo tse ikhethang: likhoele, li-slots, li-grooves, kapa machining a marang-rang a mangata.

P: Ke lisebelisoa life tseo u ka sebetsang ka tsona bakeng sa likarolo tse entsoeng ka tloaelo?

A: Re sebetsa ka lisebelisoa tse fapaneng ho fihlela litlhoko tse ikhethileng tsa kopo, ho kenyelletsa:

Litšepe: Aluminium, tšepe e sa hloekang, titanium, koporo, koporo le litšepe tsa motsoako.

Plastiki: ABS, polycarbonate, POM (Delrin), nylon, le tse ling.

Lisebelisoa tse ikhethang: Magnesium, Inconel, le lisebelisoa tse ling tse sebetsang hantle haholo.

P: Ke boholo bofe ba boholo ba likarolo tseo u ka li silang?

A: Re ka sila likarolo ka litekanyo ho fihlela ho 1,000mm x 500mm x 500mm, ho itšetlehile ka thepa le litlhoko tsa moralo.

P: Na o ka etsa li-prototypes pele ho tlhahiso ea bongata?

A: E, re fana ka lits'ebeletso tse potlakileng tsa prototyping ho netefatsa hore moralo o kopana le litlhoko tsohle tse sebetsang le tse ntle pele ho tlhahiso e felletseng.

P: Nako ea hau e tloaelehileng ea tlhahiso ke efe?

A: Linako tsa rona tsa tlhahiso li ipapisitse le ho rarahana le ho laela molumo:

Prototyping: 5-10 matsatsi a khoebo

Tlhahiso e kholo: libeke tse 2-4

P: Na likarolo tsa hau tse emisitsoeng li sebetsa hantle ka tikoloho?

A: Re ikemiselitse ho tšoarella le ho fana ka:

Lisebelisoa tsa eco-friendly

Mekhoa ea tlhahiso ea ho fokotsa litšila

Mananeo a ho tsosolosa lisebelisoa tsa tšepe

P: U ka fana ka lisebelisoa life tsa bokaholimo bakeng sa likarolo tse milled?

A: Re fana ka mefuta e fapaneng ea liphekolo tse holim'a metsi ho matlafatsa ts'ebetso, ponahalo le ts'ebetso, ho kenyelletsa:

Anodizing (e hlakileng kapa e mebala)

Ho roala nickel e se nang motlakase

Chrome plating

Ho roala ka phofo

Ho bentša, ho qhomisa lehlabathe, kapa ho qhomisa lifaha

P: U etsa bonnete ba hore likarolo tsa hau tsa milled li sebetsa joang?

A: Re kenya tšebetsong ts'ebetso e matla ea taolo ea boleng, ho kenyelletsa:

Litlhahlobo tsa maemo: Ho sebelisa lisebelisoa tsa ho lekanya tse tsoetseng pele joalo ka li-CMM.

Netefatso ea lintho tse bonahalang: Ho netefatsa hore thepa e tala e kopana le maemo a indasteri.

Teko ea ts'ebetso: Bakeng sa litlhoko tsa bohlokoa tsa ts'ebetso.