Lefatšeng le ntseng le tsoela pele la tlhahiso, likarolo tsa mochini oa CNC li lebisa phetohong. Kaha liindasteri li batla ho nepahala, ho sebetsa hantle le ho itlhophisa, theknoloji ea CNC (Computer Numerical Control) e se e le ea bohlokoa haholo, haholo-holo ho fetola ts'ebetso. Likarolo tsena tse entsoeng ka boqhetseke li matlafatsa ntho e 'ngoe le e 'ngoe ho tloha ho lienjineri tsa likoloi ho ea ho likarolo tsa sefofane, ho etsa hore likarolo tsa mochini oa CNC e be lejoe la mantlha la tsoelo-pele ea indasteri ea sejoale-joale.

Empa ke hobane'ng ha likarolo tsee li le bohlokoa hakaale, 'me li hlalosa tlhahiso bocha joang? Ha re hlahlobeng hore na ho fetola mochini oa CNC ho beha matšoao a macha joang bakeng sa ho nepahala, ts'ebetso, le katleho ea tlhahiso.

Ke Likarolo life tse Fetohang tsa CNC Machining?

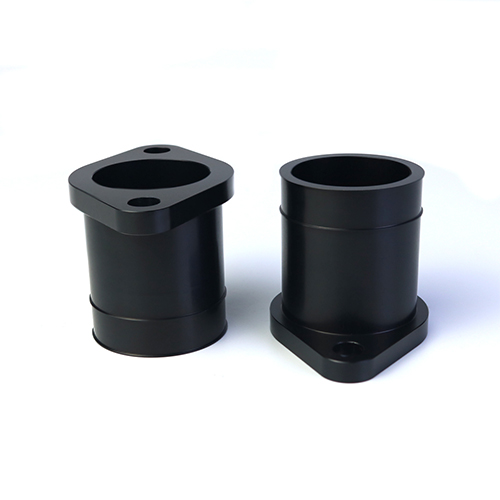

Motheong oa eona, ho fetola machining a CNC ho kenyelletsa ho tlosa thepa ho tsoa ho sesebelisoa se potolohang ho etsa libopeho tse nepahetseng tsa cylindrical. Ts'ebetso ena e etsoa ka lisebelisoa tse tsoetseng pele haholo tsa CNC, tse hlophisitsoeng ho hlahisa likarolo ka nepo le botsitso bo ikhethang.

Mehlala e tloahelehileng ea ho fetola likarolo tsa mochini oa CNC e kenyelletsa li-shafts, bushings, spindles, screws le flanges, tseo kaofela li hlokang ho nepahala ho phahameng ho netefatsa ts'ebetso e se nang moeli lits'ebetsong tsa tsona tse fapaneng.

Ho fapana le mekhoa e tloaelehileng ea ho fetola, mechine ea CNC e ka hlahisa likarolo tse nang le mamello ea micron-level, e leng se etsang hore e be tse loketseng liindasteri moo esita le ho kheloha ho honyenyane ho ka senyang ts'ebetso, joalo ka sefofane, lisebelisoa tsa bongaka, likoloi le lisebelisoa tsa elektronike.

Hobaneng ha Likarolo tsa Machining tsa CNC li Fetola

1. Ho Nepahala ho sa Bapiseng

Precision ke lets'oao la ho fetola mochini oa CNC. Li-lathe tsa sejoale-joale tsa CNC li na le lisebelisoa tsa morao-rao le lisebelisoa tse nolofalletsang baetsi ho hlahisa likarolo ka nepo e makatsang.

Mohlala, likaroloana tsa sepakapaka joalo ka lithapo tsa turbine kapa li-implants tsa bongaka joalo ka likurufu tsa masapo li hloka geometry e phethahetseng ho sebetsa kamoo ho reriloeng. Ho fetoha ha CNC ho netefatsa hore likarolo tsena li finyella litekanyetso tse thata tsa boleng, ho tlosa likotsi tse amanang le liphoso tsa matsoho.

2. Keketseho e Ntle ea Tlhahiso

Mechini e fetolang CNC e sebetsa ka lebelo le holimo ha e ntse e boloka botsitso ho pholletsa le lits'ebetso tse kholo tsa tlhahiso. Ho fapana le li-lathes tsa letsoho, tse hlokang tlhokomelo ea kamehla ea motho, lisebelisoa tsa CNC li ka sebetsa ka boithaopo, tsa fokotsa haholo nako ea tlhahiso le litšenyehelo tsa basebetsi.

Bakeng sa liindasteri tse hlahisang likarolo tse ngata tse fetotsoeng, tse kang mechine ea likoloi kapa ea indasteri, theknoloji ea CNC e lumella ho etsa lihlahisoa tse potlakileng, tse nang le litšenyehelo tse ngata ntle le boleng ba sehlabelo.

3. Customization e ntlafetseng

Ho tenyetseha ha machining a CNC ho lumella bahlahisi ho hlahisa likarolo tsa moetlo tse etselitsoeng lits'ebetso tse ikhethileng. Ka software e tsoetseng pele ea CAD/CAM, lienjiniere li ka rala lijeometri tse rarahaneng le ho li fetolela ka kotloloho mananeong a CNC.

Ebang ke prototype e le 'ngoe kapa karolo ea likarolo tse tloaelehileng bakeng sa lienjine tse sebetsang hantle haholo, ho fetoha ha CNC ho fana ka tokoloho e ke keng ea lekanngoa ea moralo. Sena se bohlokoa haholo makaleng a kang li-motorsports le thepa ea mabothobotho, moo likarolo tse ikhethang, tse sebetsang hantle li batloang haholo.

4. Tšebelisano e Phahameng ea Lintho

Mechini e fetolang CNC e khona ho sebetsana le mefuta e mengata ea lisebelisoa, ho tloha ho litšepe tsa setso tse kang aluminium, tšepe le koporo, ho ea ho li-alloys tse tsoetseng pele le metsoako e kang titanium le carbon fiber.

Ho feto-fetoha hona ho thusa bahlahisi ho fihlela litlhoko tse fapaneng tsa liindasteri tse hlokang lisebelisoa tse nang le thepa e ikhethileng, joalo ka likarolo tse bobebe tsa sefofane kapa li-implants tsa bongaka tse hananang le ho bola.

Tlhokahalo ea Likopo tsa ho Fetola Likarolo tsa Machining tsa CNC

1.Indasteri ea Likoloi

Ho fetola likarolo tsa mochini oa CNC ho bohlokoa lekaleng la likoloi, ho hlahisa likarolo tsa bohlokoa joalo ka lipiston tsa enjine, li-gear shafts le likarolo tsa ho tsamaisa. Ho nepahala le ho tšoarella ha likarolo tse fetoletsoeng tsa CNC ho netefatsa ts'ebetso e nepahetseng ea koloi, ts'ebetso e ntle le polokeho.

2.Boenjiniere ba Aerospace

Sebakeng sa sefofane, ha ho sebaka sa phoso. Likarolo tse fetotsoeng tsa CNC joalo ka lifate tsa sefofane, lisebelisoa tsa lisebelisoa tsa ho theola, le li-turbine shafts li entsoe ka mokhoa o hlakileng ho fihlela litlhoko tse matla tsa maemo a sefofane.

3.Lisebelisoa tsa Bongaka

Indasteri ea bongaka e itšetlehile haholo ka machining a CNC bakeng sa ho hlahisa lisebelisoa tsa ho buoa, li-implants le li-prosthetics. Ho fetola machining a CNC ho netefatsa hore likarolo tsena ha li nepahale feela empa hape li sebelisana hantle le lintho tse phelang ebile li bolokehile hore li ka sebelisoa lits'ebetsong tse hlokolosi.

4.Tsa elektroniki

Ho tloha ho lihokelo tse nyane ho isa ho lisinki tsa mocheso, ho fetoha ha CNC ho bapala karolo ea bohlokoa indastering ea lisebelisoa tsa elektroniki. Bokhoni ba ho sebetsa ka thepa e bonojoana le ho hlahisa likaroloana tse nyane, tse rarahaneng li entse hore phetoho ea CNC e be ea bohlokoa haholo lefapheng lena.

Tsoelo-pele ea Theknoloji ho CNC Turning

Sebaka sa ho fetoha ha CNC se ntse se tsoela pele ka potlako, ka mekhoa e mecha e ntlafatsang lebelo, ho nepahala le ts'ebetso:

1. Multi-Axis CNC Lathes

Li-lathe tsa CNC tsa sejoale-joale li na le bokhoni ba li-axis tse ngata, tse nolofalletsang lijeometri tse rarahaneng hore li hlahisoe ka mokhoa o le mong. Sena se felisa tlhokahalo ea ts'ebetso ea bobeli, ho fokotsa nako ea tlhahiso le litšenyehelo.

2. IoT Integration

Mechini e bohlale ea CNC e nang le li-sensor tsa IoT e lumella ho lekola ts'ebetso ea machining ka nako ea nnete, ho netefatsa taolo ea boleng le tlhokomelo e boletsoeng esale pele.

3. E tsoetseng pele Cutting Tools

Nts'etsopele ea lisebelisoa tsa ho itšeha tse nang le ts'ebetso e phahameng, joalo ka li-carbide tse kentsoeng ka daemane kapa tse koahetsoeng, li ntlafalitse ts'ebetso ea machining le bophelo bo atolositsoeng ba lisebelisoa, leha o sebetsa ka thepa e thata joalo ka titanium kapa Inconel.

Bokamoso ba ho Fetola likarolo tsa Machining tsa CNC

Ha liindasteri li ntse li tsoela pele ho batla ho nepahala le ho sebetsa hantle, ho fetola mochini oa CNC ho tla bapala karolo ea bohlokoa le ho feta. Ho kopanngoa ha bohlale ba maiketsetso le boits'oaro bo mothating oa ho etsa hore mechini ea ho fetola CNC e be bohlale le ho feta, e lumellang hore ho be le tlhophiso e kholo le potoloho ea tlhahiso e potlakileng.

Ho feta moo, ka ts'ebetso ea ho ts'oara, mochini oa CNC o sebelisa mekhoa e metle ea tikoloho, joalo ka ho fokotsa litšila tsa thepa ka mekhoa e ntlafalitsoeng ea mochini le ho sebelisa lisebelisoa tse ka sebelisoang hape.

Qetello: Ho fetola likarolo tsa CNC Machining joalo ka Sehlomathiso sa Tsoelo-pele

Ho phahama ha likarolo tsa mochini oa CNC ho bontša tsoelo-pele e kholo bakeng sa indasteri ea tlhahiso. Ka ho kopanya ho nepahala, ho sebetsa hantle, le ho feto-fetoha ha maemo, likarolo tsena li khanna mekhoa e mecha ho pholletsa le mefuta e mengata ea likopo, ho tloha ho lipalangoang le tlhokomelo ea bophelo ho ea ho theknoloji le ts'ireletso.

Ha theknoloji ea CNC e ntse e tsoela pele, menyetla ea ho fetola likarolo tsa mochini oa CNC ha e na moeli. Bakeng sa bahlahisi ba ikemiselitseng ho lula ba le tlholisano lefatšeng le fetohang ka potlako, ho tsetela ho matla a ho fetola CNC ha se khetho feela - ke tlhokahalo.

Hore na ke ho matlafatsa likoloi tsa moloko o latelang, ho thusa lisebelisoa tsa bongaka tse pholosang bophelo, kapa ho theha lisebelisoa tsa elektroniki tsa kamoso, likarolo tsa mochini oa CNC li ka pele ho tlhahiso e nepahetseng lekholong la bo21 la lilemo.

Nako ea poso: Jan-06-2025