La 18 Phupu 2024- Ha mahlale a machining a CNC a ntse a fetoha ka ho rarahana le bokhoni, tlhoko ea basebetsi ba nang le boiphihlelo indastering ea machining ha e so ka e ba boima le ho feta. Lipuisano tse mabapi le nts'etsopele ea litsebo le mehato ea koetliso ea basebetsi li bohlokoa ho netefatsa hore indasteri e ka tobana le liphephetso tsa hajoale le tsa kamoso.

Mathata a ntseng a eketseha a CNC Machining

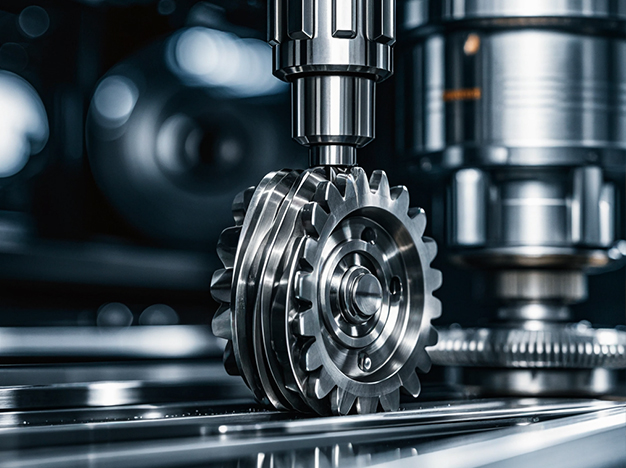

Ka tsoelopele ho machining ea CNC (Computer Numerical Control), ho kenyeletsoa kopanyo ea li-automation le mahlale a bohlale, bokhoni bo hlokahalang bakeng sa li-operators le baetsi ba mananeo bo eketsehile haholo. Mechini ea sejoale-joale ea CNC ha e hloke feela tsebo ea lits'ebetso tsa machining empa hape e hloka kutloisiso e matla ea mananeo a software le tlhokomelo ea sistimi.

Mark Johnson, moenjineri ea phahameng oa CNC o re: "Basebelisi ba kajeno ba CNC ba tlameha ho ba le motsoako oa tsebo ea tekheniki le monahano oa tlhahlobo. "Ho rarahana ha ho hlophisa le ho sebelisa mechini ena ho hloka koetliso e khethehileng ho boloka ts'ebetso le boleng."

Mananeo a Khethehileng a Koetliso

Ho rarolla lekhalo la litsebo, baetapele ba indasteri le litsi tsa thuto ba sebelisana 'moho ho theha mananeo a khethehileng a koetliso. Mananeo ana a shebana le libaka tsa bohlokoa joalo ka mananeo a CNC, ts'ebetso le tlhokomelo.

1.CNC Programming:Maiteko a lithupelo a ntse a etsoa ho ruta batho ba batlang ho sebetsa ka machini ka boqhetseke ba G-code le M-code programming. Tsebo ena ea motheo e bohlokoa bakeng sa ho theha litaelo tse nepahetseng tsa mochini.

2. Koetliso ea Ts'ebetso:Koetliso ea matsoho mabapi le ts'ebetso ea mochini e netefatsa hore basebetsi ha ba utloisise feela mokhoa oa ho tsamaisa mochini oa CNC empa hape le ho rarolla mathata a tloaelehileng le ho ntlafatsa ts'ebetso.

3. Tsebo ea ho hlokomela:Ka ho itšetleha ho eketsehileng ka mechine e tsoetseng pele, koetliso ea tlhokomelo e bohlokoa. Mananeo a totobatsa mekhoa e thibelang ho lokisoa ho lelefatsa bophelo ba mochini le ho fokotsa nako ea ho theoha.

Talenta ea ho Hohela le ho Boloka

Ha indasteri ea machining e tobane le khaello ea litalenta e ntseng e atamela, ho hohela le ho boloka basebetsi ba nang le boiphihlelo e se e le eona ntho e tlang pele. Bahiri ba sebelisa maano a fapaneng ho theha tikoloho e khahlang haholoanyane ea mosebetsi.

1. Competitive Compensation:Likhamphani tse ngata li ntse li lekola liphutheloana tsa tsona tsa matšeliso ho fana ka meputso ea tlholisano le melemo e bonts'ang litsebo tse ikhethileng tse hlokahalang tšimong.

2.Menyetla ea Tsoelo-pele ea Mosebetsi:Bahiri ba khothaletsa mekhoa ea kholo ea mosebetsi, ho kenyeletsoa mananeo a boeletsi le koetliso e tsoetseng pele, ho khothaletsa ho boloka nako e telele.

3.Tšebelisano le Mekhatlo ea Thuto:Likamano le likolo tsa theknoloji le likoleche tsa sechaba li bohlokoa bakeng sa ho aha lipeipi tsa basebetsi ba nang le litsebo. Li-Internship le mananeo a co-op a fa baithuti boiphihlelo bo sebetsang le ho pepeseha indastering.

Seabe sa Thekenoloji Koetlisong

Tsoelo-pele ea theknoloji e boetse e fetola koetliso ea basebetsi. Virtual reality (VR) le augmented reality (AR) li ntse li sebelisoa ka ho eketsehileng ho theha liphihlelo tsa koetliso tse tebileng. Litheknoloji tsena li lumella barupeluoa ho itloaetsa ts'ebetso ea CNC le ho etsa mananeo sebakeng se sireletsehileng le se laoloang.

Dr. Lisa Chang, setsebi sa thuto ea mosebetsi oa matsoho o re: “Ho sebelisa VR koetlisong ha ho hōlise kutloisiso feela empa ho boetse ho haha kholiseho tabeng ea ho sebetsana le mechine e rarahaneng.

Ho Sheba Pele

Ha boemo ba machining ba CNC bo ntse bo fetoha, matsete a tsoelang pele ho nts'etsopele ea litsebo le koetliso ea basebetsi e tla ba bohlokoa. Bankakarolo ba indasteri ba tlameha ho dula ba ikemiseditse ho hodisa basebetsi ba nang le bokgoni ba kgonang ho fihlela ditlhoko tsa mmaraka o fetohang ka potlako.

Qetello

Bokamoso ba mochini oa CNC bo itšetlehile ka nts'etsopele ea basebetsi ba nang le boiphihlelo ba nang le lisebelisoa le koetliso e hlokahalang. Ka ho tsetela mananeong a khethehileng a koetliso le ho theha tikoloho e khahlehang bakeng sa talenta, indasteri ea machining e ka netefatsa phaephe e matla ea litsebi tse nang le boiphihlelo tse ikemiselitseng ho sebetsana le mathata a mahlale a morao-rao a machining.

Nako ea poso: Aug-02-2024