Ha liindasteri tsa lefats'e li ntse li loanela ho sebetsa hantle, ho tšoarella, le ho nepahala ho nts'etsopele ea lihlahisoa,CNC ho itšeha ka tšepee hlahile e le tšiea ea bohlokoa eatlhahiso ea litsebi. Ho tloha ho likarolo tsa sefofane ho ea ho lisebelisoa tsa bongaka le lisebelisoa tsa likoloi, bahlahisi ba itšetlehile ka tse tsoetseng peleCNC(Computer Numerical Control) mahlale a ho seha tšepe ho fana ka boleng bo ke keng ba lekanngoa ka tekanyo. CNC Metal Cutting: Motheo oa Indasteri ea Sejoale-joale

CNC Metal Cutting: Motheo oa Indasteri ea Sejoale-joale

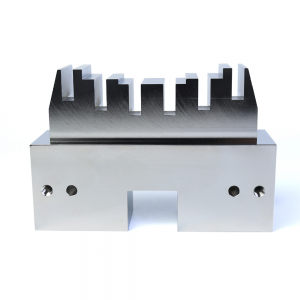

CNC tšepe ho itšeha ho bolela tšebeliso ea mechine e laoloang ke k'homphieutha ho bopa le ho tlosa lintho tse entsoeng ka tšepe. Ka ho sebelisa li-lathe, li-mill, lasers, le li-cutters tsa plasma, litsamaiso tsa CNC li fana ka ho nepahala ho ke keng ha bapisoa, ho pheta-pheta, le lebelo.

Ho Tsamaisa Boqapi ho Makala a Bohlokwa

Ho itšeha ka tšepe ea CNC ho fetotse tlhahiso ho liindasteri tse fapaneng:

• Sepakapaka:Likarolo tse rarahaneng tsa titanium, likarolo tsa turbine, le li-brackets tsa sebopeho li entsoe ka nepo ho mamella khatello e matla le maemo a mocheso.

•Likoloi:Li-engine blocks, li-transmission housings, le likaroloana tsa mariki li hahiloe ka litekanyetso tse nepahetseng bakeng sa tlhahiso ea bongata.

•Theknoloji ea Bongaka:Lisebelisoa tsa ho buoa, li-implants tsa masapo, le liforeimi tsa lisebelisoa tsa tlhahlobo li khaotsoe ka tšepe e sa hloekang le titanium ka li-finishing tse lumellanang le biocompatible.

•Lekala la Matla:Mechini ea CNC e hlahisa likarolo tse kentsoeng hantle bakeng sa li-turbine, liphaephe, le liphaephe tsa betri tse nang le litlhoko tse phahameng tsa nako e telele.

Baetsi ba litsebi hona joale ba sebelisa CNC ho itšeha ka tšepe ho netefatsa boleng bo tsitsitseng, ho ntlafatsa ts'ebetso, le ho fokotsa linako tse etellang pele - tsohle li bohlokoa mebarakeng ea lefatše e nang le tlholisano e kholo.

Theknoloji ka Mora Phetoho

CNC ho itšeha tšepe ho kenyelletsa mekhoa e mengata ea theknoloji e phahameng, ho kenyelletsa:

•Ho sila le ho Fetola:Tlosa tšepe u sebelisa lisebelisoa tsa rotary kapa lathes, tse loketseng libopeho tse rarahaneng le mamello e thata.

•Ho khaola ka Laser:E sebelisa li-laser tse matla haholo ho qhibilihisa kapa ho etsa mouoane oa tšepe ka nepo e feteletseng - e loketse maqephe a masesaane le meralo e rarahaneng.

•Ho itšeha ka Plasma:E sebelisa khase ea ionized ho khaola litšepe tse teteaneng kapa tse tsamaisang kapele le ka mokhoa o nepahetseng.

•Wire EDM (Motlakase oa ho Lahla Motlakase):E thusa ho khaola litšepe tse thata ka ho fetesisa ntle le ho sebelisa matla a tobileng, hangata a sebelisoang tlhahisong ea lisebelisoa le lihlahisoa.

Ka tlatsetso ea machining a li-multi-axis, tlhahlobo ea matla a AI, le mafahla a dijithale, mechini ea kajeno ea ho seha tšepe ea CNC e bohlale ebile e tenyetseha ho feta leha e le neng pele.

Smart Manufacturing le Sustainability

Sistimi ea sejoale-joale ea tšepe ea CNC e etselitsoeboiketsetso le botsitso. Li hokahana ka mokhoa o ts'oanang le liroboto le software ea taolo ea feme, e nolofalletsang tlhahiso ea mabone le netefatso ea boleng ba nako ea nnete. Ho feta moo, ntlafatso ea ts'ebeliso ea lisebelisoa le ts'ebeliso ea thepa e thusa ho fokotsa litšila le tšebeliso ea matla.

Nako ea poso: Jun-28-2025