Ha re ntse re atamela 2025, indasteri ea tlhahiso e mothating oa ho fetoha, e susumetsoang ke tsoelo-pele ea theknoloji ea ho sila ea CNC. E 'ngoe ea liphetoho tse thabisang ka ho fetisisa ke ho phahama ha nano-precision ho CNC milling, e tšepisang ho fetola tsela eo likarolo tse rarahaneng le tse phahameng li hlahisoang ka eona. Mokhoa ona o lebelletsoe ho ba le tšusumetso e kholo mafapheng a fapaneng, ho kenyeletsoa likoloi, sefofane, lisebelisoa tsa bongaka le lisebelisoa tsa elektroniki.

Nano-Precision: The Next Frontier ho CNC Milling

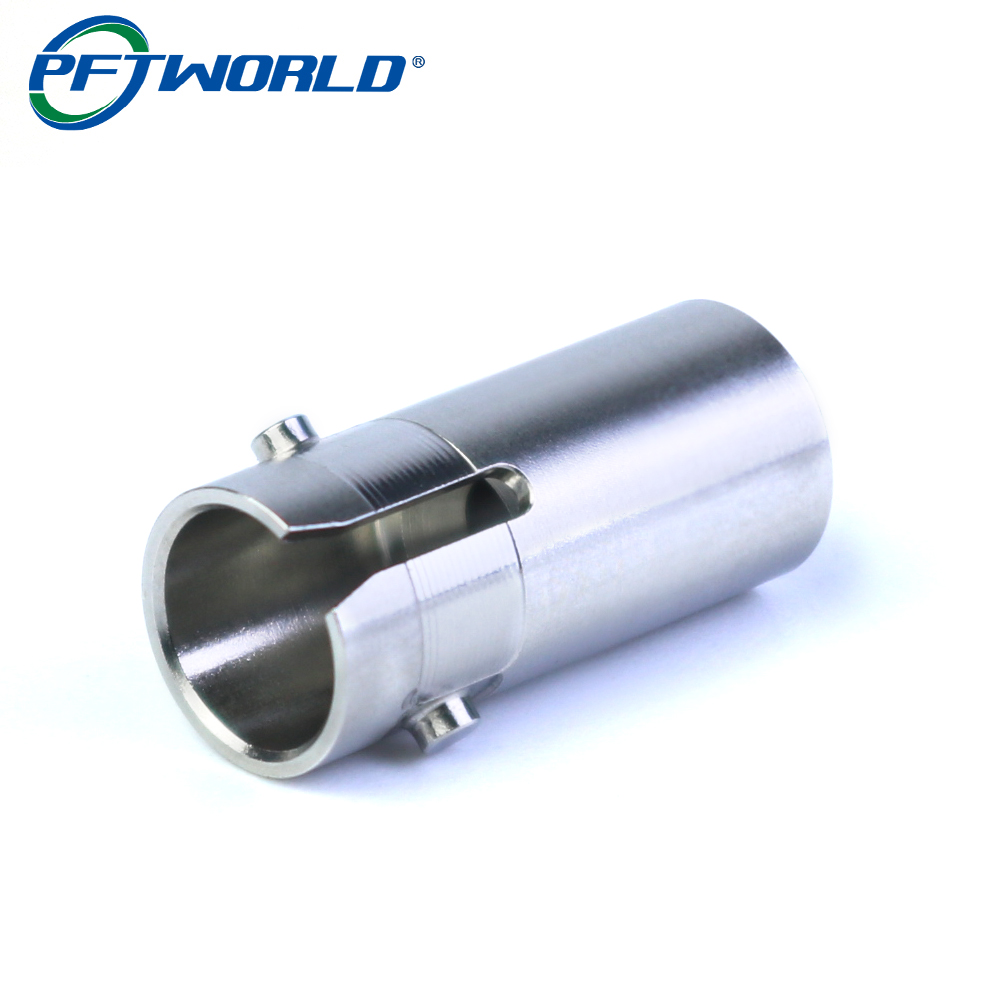

Nano-precision in CNC milling e bolela bokhoni ba ho fihlela maemo a holimo haholo a ho nepahala sekala sa nanometer. Boemo bona ba ho nepahala bo bohlokoa bakeng sa likarolo tsa tlhahiso tse nang le li-geometri tse rarahaneng le mamello e tiileng, e batloang haholo ke liindasteri tsa sejoale-joale. Ka ho sebelisa lisebelisoa tse tsoetseng pele, lisebelisoa tsa morao-rao, le software e tsoetseng pele, mechini ea ho sila ea CNC e se e khona ho hlahisa likarolo ka nepo le botsitso bo ke keng ba bapisoa.

Tsoelo-pele ea Bohlokoa Ho khanna Nano-Precision

1.Khokahano ea ho Ithuta ea AI le MochiniArtificial Intelligence (AI) le Machine Learning (ML) li bapala karolo ea bohlokoa ho ntlafatseng ho nepahala ha tshilo ya CNC. Litheknoloji tsena li thusa mechini ho ithuta ho tsoa ts'ebetsong ea nako e fetileng, ho ntlafatsa litsela tsa ho itšeha, le ho bolela esale pele hore na lisebelisoa li tla sebelisoa joang, kahoo li fokotsa liphoso le ho ntlafatsa ts'ebetso. Litsamaiso tse tsamaisoang ke AI li ka boela tsa etsa liphetoho tsa nako ea sebele, ho netefatsa hore ts'ebetso e 'ngoe le e' ngoe ea mochine e finyella litekanyetso tse phahameng ka ho fetisisa tsa ho nepahala.

2.Lisebelisoa tse tsoetseng pele le tlhahiso ea HybridTlhokahalo ea lisebelisoa tse bobebe empa tse tšoarellang joalo ka li-alloys tsa titanium, li-composites tsa carbon, le li-polymers tse matla haholo li tsamaisa tlhoko ea mekhoa e tsoetseng pele ea machining. CNC milling e ntse e tsoela pele ho sebetsana le lisebelisoa tsena tse tsoetseng pele ka nepo e kholo, ka lebaka la mahlale a morao-rao a lisebelisoa le mahlale a pholiso. Ho feta moo, ho kopanngoa ha tlhahiso ea tlatsetso (khatiso ea 3D) le CNC milling e bula menyetla e mecha ea ho theha likarolo tse rarahaneng tse nang le litšila tse fokotsehileng.

3.Automation le LirobotoAutomation e fetoha lejoe la sekhutlo la CNC milling, ka mesebetsi ea liroboto ea ho tšoara matsoho joalo ka ho kenya, ho laolla, le tlhahlobo ea karolo. Sena se fokotsa phoso ea motho, se eketsa katleho ea tlhahiso, 'me se lumella ts'ebetso ea 24/7. Liroboto tse sebelisanang (li-cobots) le tsona li ntse li eketseha, li sebetsa hammoho le batho ba sebetsang ho ntlafatsa tlhahiso.

4.Mekhoa e Tsoelang PeleSustainability ke ntho e tlang pele ho nts'etsopele ea tlhahiso, 'me ho roala ha CNC ho joalo. Baetsi ba sebelisa mekhoa e metle ea tikoloho joalo ka mechini e baballang matla, lisebelisoa tse ka sebelisoang hape, le lisebelisoa tse pholisang tse koetsoeng ho fokotsa tšusumetso ea tikoloho. Mekhoa ena e mecha ha e fokotse litšila feela empa e boetse e fokotsa litšenyehelo tsa ts'ebetso, e leng se etsang hore ho sila ha CNC ho tšoarelle le ho boloka chelete e ngata.

5.Digital Twins le Virtual SimulationTheknoloji ea mafahla ea dijithale-ho theha likopi tsa sistimi ea 'mele-e lumella baetsi ho etsisa mekhoa ea ho sila ea CNC pele ho tlhahiso. Sena se netefatsa litlhophiso tse nepahetseng tsa mochini, se fokotsa litšila, 'me se tsebahatsa mathata a ka bang teng esale pele, e leng se lebisang ho nepahala le ho sebetsa hantle haholo.

Tšusumetso ho Liindasteri tsa Bohlokoa

•Tsa makoloi: Nano-precision in CNC milling e tla thusa ho hlahisa likarolo tsa enjene tse bobebe, tse sebetsang hantle le likarolo tsa phetiso, ho kenya letsoho ntlafatsong ea moruo le ts'ebetso ea mafura.

•Sepakapaka: Bokhoni ba ho sebetsana le thepa e tsoetseng pele ka nepo e phahameng e tla ba ea bohlokoa bakeng sa ho etsa likarolo tse rarahaneng joalo ka li-blade tsa turbine le likarolo tsa sebopeho sa sefofane.

•Lisebelisoa tsa Bongaka: Ho sila ka mokhoa o phahameng oa CNC ho tla phetha karolo ea bohlokoa ho hlahiseng li-implants tse tloaelehileng, lisebelisoa tsa ho buoa, le lisebelisoa tsa ho hlahloba, ho ntlafatsa liphello tsa mokuli le katleho ea phekolo.

•Tsa elektroniki: Tloaelo e lebisang ho miniaturization ka lisebelisoa tsa elektronike e tla rua molemo ho nano-precision, e lumellang bahlahisi ho hlahisa likarolo tse nyenyane, tse matla haholoanyane.

Ho phahama ha nano-precision ho CNC milling ho behiloe ho hlalosa bocha meeli ea se ka khonehang tlhahisong. Ka ho sebelisa AI, lisebelisoa tse tsoetseng pele, le litloaelo tse tšoarellang, CNC milling e tla tsoela pele ho tsamaisa boqapi le katleho liindasteri tse fapaneng. Ha re ntse re lebelletse 2025, bokamoso ba tlhahiso bo shebahala bo khanya ebile bo nepahetse ho feta neng kapa neng.

Nako ea poso: Mar-12-2025