Magnetic vs Pneumatic Workholding for Thin Sheet Aluminium

Mongoli: PFT, Shenzhen

Kakaretso

Ho sebetsa ka nepo ha aluminium sheet sheet (<3mm) ho tobane le mathata a bohlokoa a ho sebetsa. Boithuto bona bo bapisa litsamaiso tsa likhohlopo tsa makenete le tsa moea tlas'a maemo a laoloang a CNC. Mekhahlelo ea liteko e ne e kenyelletsa ho tsitsisa ha matla a ho tiisa, botsitso ba mocheso (20°C–80°C), ho thothomela, le ho sothofala ha bokaholimo. Pneumatic vacuum chucks e ile ea boloka sephara sa 0.02mm bakeng sa maqephe a 0.8mm empa e ne e hloka libaka tse tiisitsoeng tse tiileng. Li-chuck tsa motlakase li nolofalelitse phihlello ea 5-axis le ho fokotsa nako ea ho seta ka 60%, leha ho le joalo maqhubu a eddy a bakileng ho futhumatsa sebakeng se fetang 45 ° C ho 15,000 RPM. Liphetho li bonts'a lisebelisoa tsa vacuum li ntlafatsa bokaholimo bakeng sa maqephe > 0.5mm, ha litharollo tsa makenete li ntlafatsa ho tenyetseha bakeng sa prototyping e potlakileng. Meeli e kenyelletsa mekhoa e nyalisitsoeng e sa lekoang le mefuta e meng e thehiloeng ho sekhomaretsi.

1 Selelekela

Lipampiri tse tšesaane tsa aluminium liindasteri tsa matla ho tloha ho aerospace (matlalo a fuselage) ho ea ho tsa elektroniki (ho etsa sink ea mocheso). Leha ho le joalo liphuputso tsa indasteri ea 2025 li senola 42% ea liphoso tse nepahetseng li tsoa ho motsamao oa li-workpiece nakong ea machining. Li-clamps tse tloaelehileng tsa mechine li atisa ho sotha maqephe a ka tlaase ho 1mm, ha mekhoa e thehiloeng ho theipi e haelloa ke ho tiea. Boithuto bona bo fana ka litharollo tse peli tse tsoetseng pele: li-chucks tsa electromagnetic leveraging control remanence system le sistimi ea pneumatic e nang le taolo ea vacuum ea libaka tse ngata.

2 Mokhoa

2.1 Moralo oa Teko

-

Lisebelisoa: maqephe a aluminium a 6061-T6 (0.5mm / 0.8mm / 1.2mm)

-

Thepa:

-

Magnetic: GROB 4-axis electromagnetic chuck (0.8T field intensity)

-

Moea oa moea: Letlapa la vacuum la SCHUNK le nang le mefuta e mengata ea libaka tse 36

-

-

Teko: Bophahamo ba sefahleho (laser interferometer), setšoantšo sa mocheso (FLIR T540), tlhahlobo ea vibrate (3-axis accelerometers)

2.2 Liteko tsa Liteko

-

Static Stability: Lekanya ho kheloha tlas'a matla a lateral a 5N

-

Thermal Cycling: Rekota li-gradients tsa mocheso nakong ea ho sila (Ø6mm end mill, 12,000 RPM)

-

Matla a Matla: Lekanya boholo ba ho thothomela ka maqhubu a resonant (500–3000 Hz)

3 Liphetho le Tlhahlobo

3.1 Ts'ebetso ea Clamping

| Paramethara | Moea oa moea (0.8mm) | Magnetic (0.8mm) |

|---|---|---|

| Avg. Phetolo | 0.02 limilimithara | 0.15 limilimithara |

| Nako ea ho Seta | 8.5 mets | 3.2 mets |

| Max Temp Rise | 22°C | 48°C |

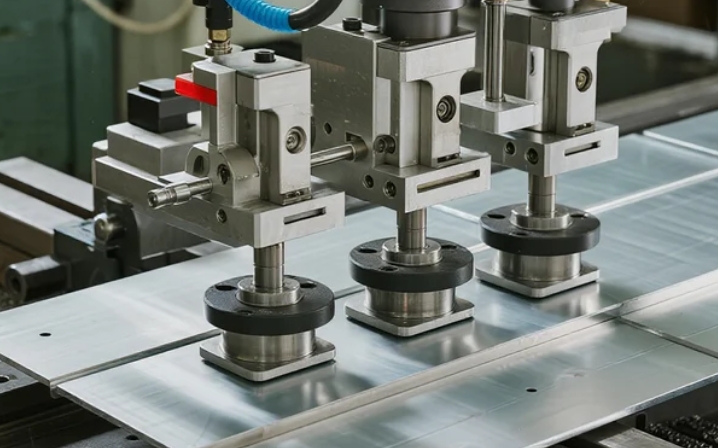

Setšoantšo sa 1: Lisebelisoa tsa vacuum li bolokiloe <5μm ho fapana ha holim'a sefahleho nakong ea ho siloa ha sefahleho, athe magnetic clamping e bonts'a 0.12mm bohale ba phahamisa ka lebaka la ho atolosoa ha mocheso.

3.2 Litšobotsi tsa ho thothomela

Pneumatic chucks attenuated harmonics ka 15dB ho 2,200Hz - ea bohlokoa bakeng sa ts'ebetso e phethehileng hantle. Ts'ebetso ea Magnetic e bonts'itse 40% bophahamo bo phahameng ho feta maqhubu a ho sebelisana le lisebelisoa.

4 Puisano

4.1 Liphetoho tsa Theknoloji

-

Molemo oa Pneumatic: Ho tsitsisa ha mocheso o phahameng le ho thothomela ho sutu e nang le mamello e phahameng joalo ka lisebelisoa tsa optical component.

-

Magnetic Edge: Tokiso e potlakileng e ts'ehetsa maemo a mabenkele a mesebetsi a sebetsanang le mefuta e fapaneng ea boholo.

Moeli: Liteko ha li kenyellelitsoe maqephe a nang le mafura kapa a mafura moo ts'ebetso ea vacuum e theohang> 70%. Litharollo tsa Hybrid li hloka thuto e tlang.

5 Qetello

Bakeng sa machining a aluminium a masesaane:

-

Ho sebetsa ka moea ho fana ka ho nepahala ho phahameng bakeng sa botenya> 0.5mm ka libaka tse sa tsitsang.

-

Sistimi ea makenete e fokotsa nako e sa seheng ka 60% empa e hloka maano a pholiso bakeng sa taolo ea mocheso

-

Khetho e nepahetseng e ipapisitse le litlhoko tsa phallo khahlano le litlhoko tsa mamello

Lipatlisiso tsa nako e tlang li lokela ho hlahloba li-clamp tse nyalisitsoeng tse feto-fetohang le meralo e nang le tšitiso e tlase ea motlakase.

Nako ea poso: Jul-24-2025