Sebakeng se ntseng se fetoha ka potlako sa tlhahiso ea sejoale-joale, ho kopanngoa ha tlhahiso ea tlatsetso (khatiso ea 3D) le machining ea setso ea CNC e hlaha e le mokhoa oa ho fetola papali. Mokhoa ona oa lebasetere o kopanya matla a mahlale a mabeli, o fana ka ts'ebetso e sa lebelloang, ho tenyetseha le ho nepahala ts'ebetsong ea tlhahiso.

The Synergy of Additive and Subtractive Manufacturing

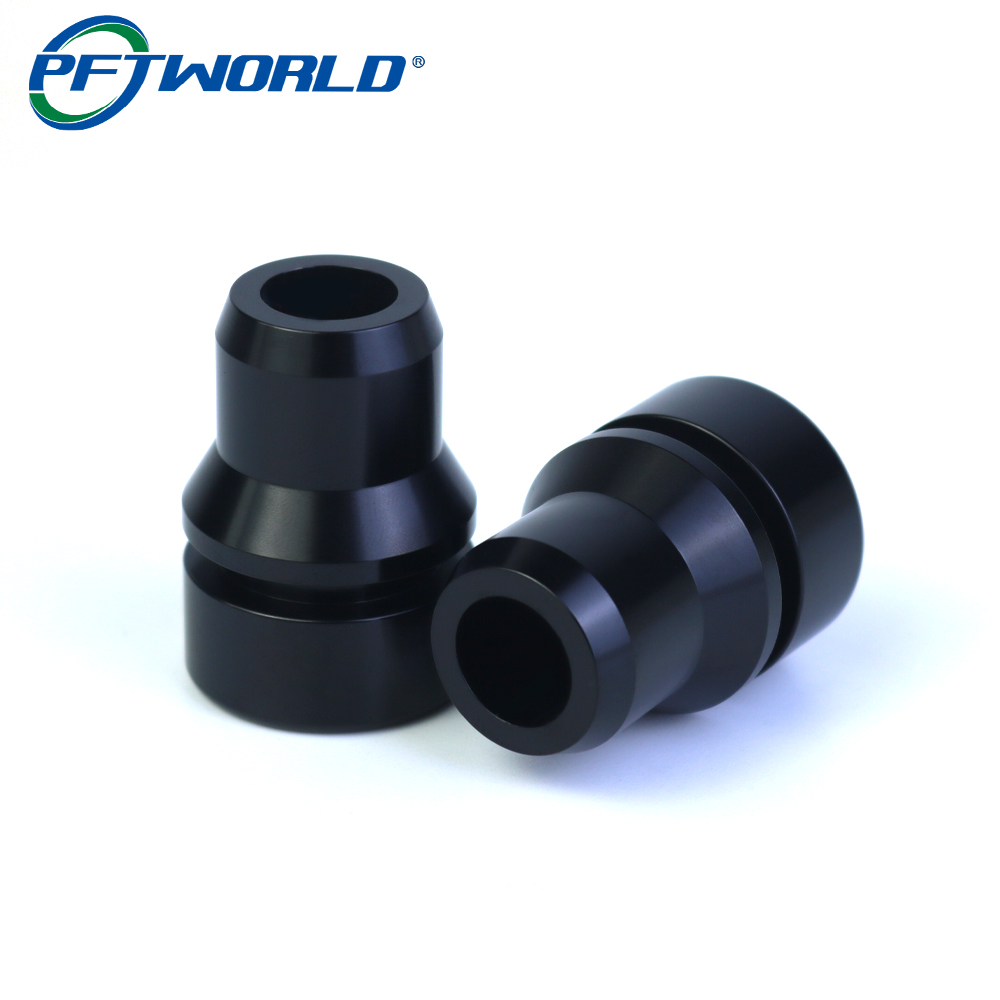

Tlhahiso e eketsang e sebetsa hantle ho theheng li-geometri tse rarahaneng le meaho e bobebe, athe machining a CNC a netefatsa ho nepahala le ho phethoa ha bokaholimo. Ka ho kopanya mekhoa ena, joale baetsi ba lintho ba ka hlahisa likarolo tse rarahaneng ka tsela e atlehileng haholoanyane. Ka mohlala, khatiso ea 3D e ka sebelisoa ho etsa likarolo tse haufi-le-net-shape, tseo ka nako eo li hloekisoang ka ho sebelisa mochine oa CNC ho finyella mamello e hlokahalang le boleng ba holim'a metsi.

Mokhoa ona oa lebasetere ha o fokotse litšila tsa thepa feela empa o boetse o tsamaisa nako ea tlhahiso. Baetsi ba ka hlahisa li-prototype le likarolo tsa tloaelo ka potlako, ba fokotsa linako tsa ho etella pele le ho ntlafatsa tlhahiso ka kakaretso.

Tsoelo-pele ho Lits'ebetso tsa Hybrid Manufacturing Systems

Sistimi ea sejoale-joale ea hybrid e kopanya mekhoa ea tlatsetso le e fokotsang ka har'a mochini o le mong, e lumellang phetoho e se nang moeli lipakeng tsa ho aha thepa le ho e theola. Litsamaiso tsena li phahamisa software e tsoetseng pele le li-algorithms tse tsamaisoang ke AI ho ntlafatsa ts'ebetso ea tlhahiso. Mohlala, AI e ka sekaseka meralo ea likarolo ho bona motsoako o sebetsang ka ho fetesisa oa mehato e tlatselletsang le e fokotsang, ho netefatsa tšebeliso e nepahetseng ea thepa le ho fokotsa nako ea tlhahiso.

Tšusumetso ho Liindasteri tsa Bohlokoa

1.Sepakapaka: Ho etsa li-hybrid ho molemo haholo indastering ea lifofane, moo likarolo tse bobebe empa tse matla li leng bohlokoa. Baetsi joale ba ka hlahisa likarolo tse rarahaneng joalo ka li-blade tsa turbine le likarolo tsa sebopeho ka mokhoa o atlehileng haholoanyane.

2.Tsa makoloi: Lefapheng la likoloi, tlhahiso e nyalisitsoeng e thusa ho hlahisa likarolo tse bobebe, tse kenyang letsoho ntlafatsong ea ts'ebetso ea mafura le ts'ebetso. Bokhoni ba ho etsa prototype ka potlako le ho etsa likarolo tsa hau le bona bo potlakisa ts'ebetso ea nts'etsopele.

3.Lisebelisoa tsa Bongaka: Bakeng sa lisebelisoa tsa bongaka le li-implants, motsoako oa li-additive le CNC machining o netefatsa ho nepahala le ho etsoa ka mokhoa o phahameng. Sena se bohlokoa bakeng sa ho theha lisebelisoa tse tobileng mokuli tse fihlelang litekanyetso tse thata tsa boleng.

Moshoelella le Tšebeliso ea Litšenyehelo

Ho kopanngoa ha tlhahiso ea li-additive le subtractive ho boetse ho lumellana le lipakane tsa ts'ebetso. Ka ho fokotsa litšila le tšebeliso ea matla, litsamaiso tsa tlhahiso ea lebasetere li kenya letsoho molemong oa tlhahiso e bonolo haholoanyane ea tikoloho. Ho feta moo, bokhoni ba ho hlahisa likarolo tse hlokahalang bo fokotsa litšenyehelo tsa thepa le ho fokotsa tlhoko ea polokelo e kholo.

Maikutlo a Bokamoso

Ha tlhahiso ea tlatsetso e ntse e tsoela pele, ho hokahana le mochini oa CNC ho tla ba bonolo le ho sebetsa hantle le ho feta. Lintlafatso tsa mahlale a thepa, ntlafatso ea ts'ebetso e tsamaisoang ke AI, le ho phahama ha Indasteri 5.0 ho tla ntlafatsa le ho feta bokhoni ba tlhahiso e nyalisitsoeng. Baetsi ba amohelang mokhoa ona ba tla be ba le maemong a matle ho fihlela litlhoko tse ntseng li eketseha tsa ho itloaetsa, ho sebetsa hantle le ho tšoarella lilemong tse tlang.

Ka bokhutšoanyane, ho kopanngoa ha tlhahiso ea tlatsetso le mochini oa CNC ho fetola sebopeho sa tlhahiso ka ho kopanya melemo ea mahlale a mabeli. Mokhoa ona oa lebasetere ha o ntlafatse ts'ebetso le ho nepahala feela, empa hape o ts'ehetsa lipakane tsa ts'ebetso, e leng se etsang hore e be mokhoa oa bohlokoa oa ho shebella ka 2025 le ho feta.

Nako ea poso: Mar-12-2025