Titanium's futsanehileng mocheso conductivity le phahameng lik'hemik'hale reactivity etsa hore ho le tšekamelo ea ho bokooa holim'a metsi nakongMechine ea CNC. Le ha li-geometry tsa lisebelisoa le li-parameter tsa ho itšeha li ithutoa hantle, ntlafatso ea pholiso e ntse e sa sebelisoe haholo ts'ebetsong ea indasteri. Phuputso ena (e entsoeng ka 2025) e sebetsana le lekhalo lena ka ho lekanya hore na ho fana ka pholiso ho ntlafatsa boleng ba ho qetela ntle le ho senya tlhahiso.

Mokhoa

1. Moqapi oa Teko

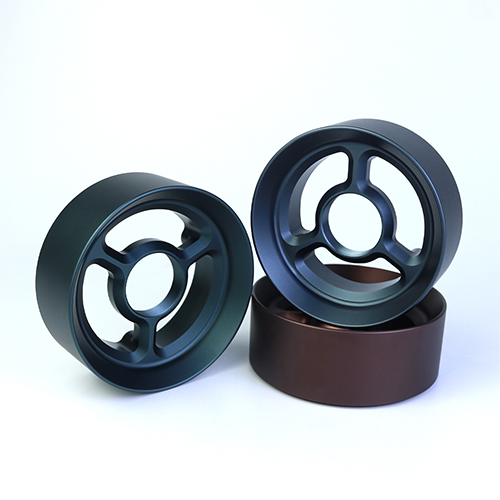

●Boitsebiso:Lithupa tsa Ti-6Al-4V (Ø50mm)

●Thepa:5-axis CNC e nang le sesebelisoa se pholisang ka har'a sesebelisoa (sebaka sa khatello: 20-100 bar)

●Metrics e lateloang:

Bokhopo bo holimo (Ra) ka ho kopana le profilometer

Ho roala mapheo a lisebelisoa ho sebelisa setšoantšo sa microscope ea USB

Mocheso oa libaka (FLIR khamera ea mocheso)

2. Repeatability Controls

● Ho pheta-pheta liteko tse tharo ho ea ka sete ea paramethara

● Lisebelisoa tsa lisebelisoa li nkeloa sebaka ka mor'a teko ka 'ngoe

● Thempereichara ea tikoloho e tsitsitse ho 22°C ±1°C

Liphetho & Analysis

1. Khatello e Pholisang vs. Surface Finish

●Khatello (bar):20 50 80

●Avg. Ra (μm) :3.2 2.1 1.4

●Tool Wear (mm):0.28 0.19 0.12

Pholiso e phahameng ea khatello (80 bar) e fokolitse Ra ka 56% khahlanong le baseline (20 bar).

2. Nozzle Positioning Liphello

Li-nozzles tse nang le mahlakore a mabeli (15° ho ea ntlheng ea sesebelisoa) li ntlafalitse litlhophiso tsa radial ka:

● Ho fokotsa ho bokellana ha mocheso ka 27% (boitsebiso ba mocheso)

● Ho eketsa bophelo ba lisebelisoa ka 30% (litekanyo tsa ho roala)

Puisano

1. Mekhoa ea Bohlokoa

●Phallo ea Chip:Setsidifatsi sa kgatello e phahameng se pshatla ditjhepisi tse telele, ho thibela ho poma hape.

●Taolo ea Mocheso:Pholiso ea sebakeng sa heno e fokotsa ho khopama ha lisebelisoa.

2. Mefokolo e Sebetsang

● E hloka litlhophiso tse fetotsoeng tsa CNC (bonyane bo boholo ba pompo ea li-bar 50)

● Ha e na litšenyehelo bakeng sa tlhahiso ea molumo o tlaase

Qetello

Ho matlafatsa khatello e pholileng le ho hokahanya ha molomo oa molomo ho ntlafatsa boleng ba titanium haholo. Baetsi ba lokela ho etelletsa pele:

● Ho ntlafatsa ho ≥80 bar coolant systems

● Ho etsa liteko tsa ho beha nozzle bakeng sa lisebelisoa tse khethehileng

Lipatlisiso tse ling li lokela ho hlahloba pholiso e nyalisitsoeng (mohlala, cryogenic+MQL) bakeng sa li-alloys tse thata-to-machine.

Nako ea poso: Aug-01-2025