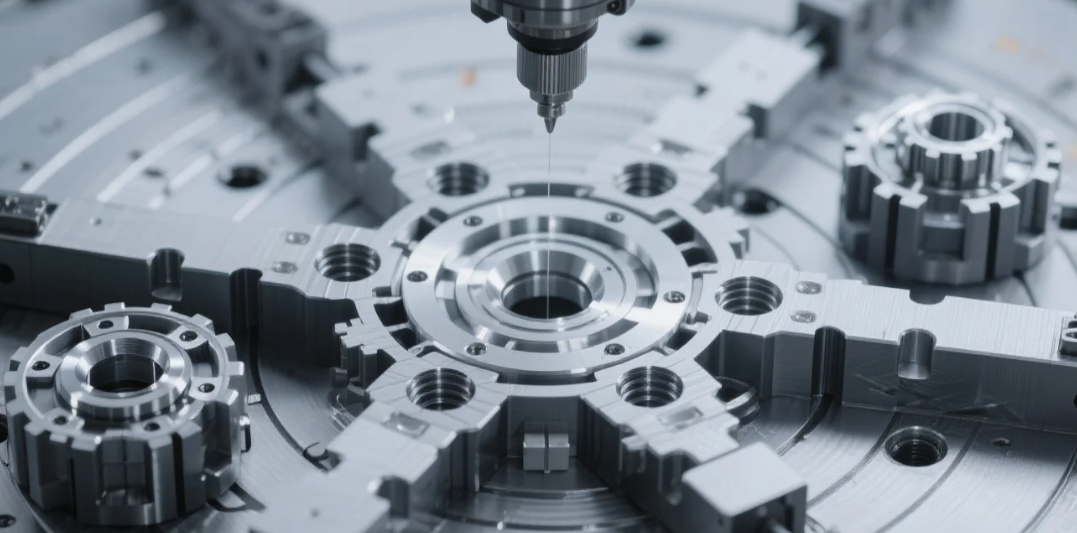

Multi-Axis CNC Machining bakeng sa Lisebelisoa tsa Optical tsa Ultra-Precision tse nang le li-Geometri tse rarahaneng

Liindastering moo ho nepahala ha boemo ba micron ho hlalosang katleho - sepakapaka, lisebelisoa tsa bongaka, li-optics tse tsoetseng pele - tlhoko eaultra-precision optical componentskali-geometri tse rarahanenge ntse e phahama. Mechini ea setso ea 3-axis CNC e loana le li-contours tse rarahaneng le mamello e thata, empamachining a multi-axis CNCe fetola sena. Feme ea rona e sebelisa theknoloji ea 5-axis CNC ho fana ka likarolo tse fihlelang maemo a thata ka ho fetesisa, ho kopanya.lisebelisoa tse tsoetseng pele,taolo ya boleng bo thata, letšehetso ea bareki e etselitsoeng.

Hobaneng ha Multi-Axis CNC Machining?

1.Precision e sa Bapisitsoeng Bakeng sa Meetso e Ratang

• Ho fapana le mechini ea 3-axis e lekanyelitsoeng metsamaong ea mela, ea ronaLitsamaiso tsa CNC tsa 5-axis(mohlala, letoto la DMU) thusa ho potoloha ka nako e le 'ngoe ho latela lilepe tsa A/B/C. Sena se lumella ho etsa libopeho tse rarahaneng - lilense tsa sebopeho sa mahala, liipone tsa aspherical - ka setupong se le seng, ho tlosa liphoso tsa ho beha maemo le ho fihlela mamello kahare.± 0.003 limilimithara.

• Mohlala: Lense ea li-curvature tse peli bakeng sa laser collimator, e hlokang <0.005mm holim'a ho kheloha, e hlahisitsoe ka ho nepahala ha 99.8%.

2.Katleho & Poloko ea Litšenyehelo

• Mechini e hlophisitsoeng e le 'ngoee fokotsa nako ea tlhahiso ka 40-60% khahlanong le mekhoa ea mekhahlelo e mengata. Bakeng sa morero oa satellite optical housing, re fokotsa nako ea ho etella pele ho tloha matsatsing a 14 ho ea ho a 6.

• Litsela tse itirisang tsa lisebelisoa li fokotsa litšila tsa lintho tse bonahalang—tse bohlokoa haholo bakeng sa li-substrates tse turang joalo ka silica e kopantsoeng kapa Zerodur®.

Tsebo e Ikhethang ea Feme ea Rona

1. Lisebelisoa tse tsoetseng pele tsa Multi-Axis

- Litsi tsa CNC tsa 5-Axis: DMU 65 monoBLOCK® (maeto: X-1400mm, Y-900mm, Z-700mm; spindle: 42,000 RPM) bakeng sa ho qeta ka lebelo le phahameng, ntle le ho thothomela.

- Li-add-on tsa Ultra-Precision: Lisebelisoa tsa laser tse kopantsoeng bakeng sa metrology ea nako ea 'nete le tokiso ea lisebelisoa tse feto-fetohang nakong ea mochini.

- Tlhokomelo ea Ts'ebetso: Karolo e 'ngoe le e' ngoe e na le li-checkpoints tse tharo:

2. Tikoloho ea Boleng bo Matla

Raw material spectrometry (ISO 17025-certified lab) .

Ho hlahloba ka mochine bakeng sa ho nepahala ha dimensional .

Netefatso ea CMM ka mor'a ts'ebetso (Zeiss CONTURA G2, ho nepahala: 1.1µm + L/350µm) .

•Ho lumellana ha ISO 9001/13485: Litlaleho tsa mosebetsi tse ngotsoeng li netefatsa hore ho na le traceability ho tloha ho moralo ho isa ho phano.

3. Lintho Tse sa Tšoaneng le Tsebo ea Tšebeliso

Lisebelisoa: Khalase ea optical, ceramics, titanium, Inconel®.

Lisebelisoa: Li-endoscopes, lihlopha tsa lense tsa VR, li-collimator tsa fiber-optic, li-reflectors tsa sefofane.

4. Tšehetso ea Bareki ea ho Qetela

•Tšebelisano 'moho: Baenjiniere ba rona ba ntlafatsa meralo bakeng sa tlhahiso ea tlhahiso (DFM) - mohlala, ho nolofatsa mekhoa e tlase ho fokotsa litšenyehelo.

•Tiisetso ea Kamor'a Phano:

o24/7 hotline ea tekheniki (<30-metsotso ea karabo) .

oTšehetso ea tlhokomelo ea bophelo bohle + waranti ea lilemo tse 2.

oLisebelisuoa tsa likarolo tse ling: Ho tsamaisoa ha lefatše nakong ea lihora tse 72.

Thuto-pale: Lense ea Boikemisetso ba Maekerosekoupo e Phahameng-NA

Phephetso: Moreki oa bongaka o ne a hloka lilense tse 200 tse nang le li-micro-grooves (botebo: 50µm ±2µm) bakeng sa ho tataisa leseli la metsi.

Tharollo:

•CNC ea rona ea 5-axis e hlophiselitse litselana tsa lithulusi tsa elliptical tse nang le li-angles tse sekamang tse fapaneng.

•Ho sekena ka laser ha ho ntse ho lemohuoa ho fapoha >1µm, ho etsa hore motho a lokisoe.

Sephetho: 0% sekhahla sa ho hana; 98% ea ho fana ka nako.

Lipotso: Ho sebetsana le Matšoenyeho a Bohlokoa a Bareki

P: Na u ka sebetsana le li-geometri ka li-undercuts kapa li-symmetry tse sa potolohang?

A: Ho joalo. Litafole tsa rona tsa 5-axis CNC's tilt-rotary angles li fihlella li-angles tse fihlang ho 110°, likarolo tsa machining joalo ka likanale tsa helical kapa libaka tsa parabolic tse kantle ho axis ntle le ho hlophisoa bocha.

P: U etsa bonnete ba hore optical surface e tšepahala?

A: Re sebelisa lisebelisoa tse koahetsoeng ka daemane tse nang le li-cycle tsa nano-polishing, ho finyella ho hlaka holimo (Ra) <10nm-e bohlokoa bakeng sa lisebelisoa tsa laser .

P: Ho thoe'ng haeba ke hloka liphetoho tsa moralo ka mor'a tlhahiso?

K: Sebaka sa rona sa marang-rang se thehiloeng marung se u lumella ho fana ka lintlafatso, ka lipapiso tse ntlafalitsoeng tse tlisoang ka mor'a matsatsi a 5-7.

P: Ke eng'na sebaka sa khoebo ea hau?

A: Tšebeletso ea OEM. Sebaka sa rona sa khoebo ke CNC lathe e sebetsitsoeng, ho phethoha, ho hatakela, joalo-joalo.

Q.U ka ikopanya le rona joang?

A: U ka romella lipotso tsa lihlahisoa tsa rona, li tla arajoa nakong ea lihora tse 6; 'me u ka ikopanya le rona ka tsela e sa tobang ka TM kapa WhatsApp, Skype kamoo u ratang.

P. Ke tlhahisoleseding efe eo ke lokelang ho o fa yona bakeng sa ho botsisisa?

A: Haeba u na le litšoantšo kapa lisampole, pls ikutloe u lokolohile ho re romella, 'me u re bolelle litlhoko tsa hau tse khethehileng tse kang thepa, mamello, phekolo ea holim'a metsi le chelete eo ue hlokang, joalo-joalo.

Q. Ho thoe'ng ka letsatsi la ho pepa?

A: Letsatsi la ho fana ke matsatsi a ka bang 10-15 ka mor'a ho fumana tefo.

Q. Ho thoe'ng ka lipehelo tsa tefo?

A: Ka kakaretso EXW KAPA FOB Shenzhen 100% T / T esale pele, 'me re ka boela ra buisana accroding ho tlhokahalo ea hao.