Litšebeletso tse Ikemetseng tsa ho Hlōla Litšepe, Ho Seha, le ho Pholisa

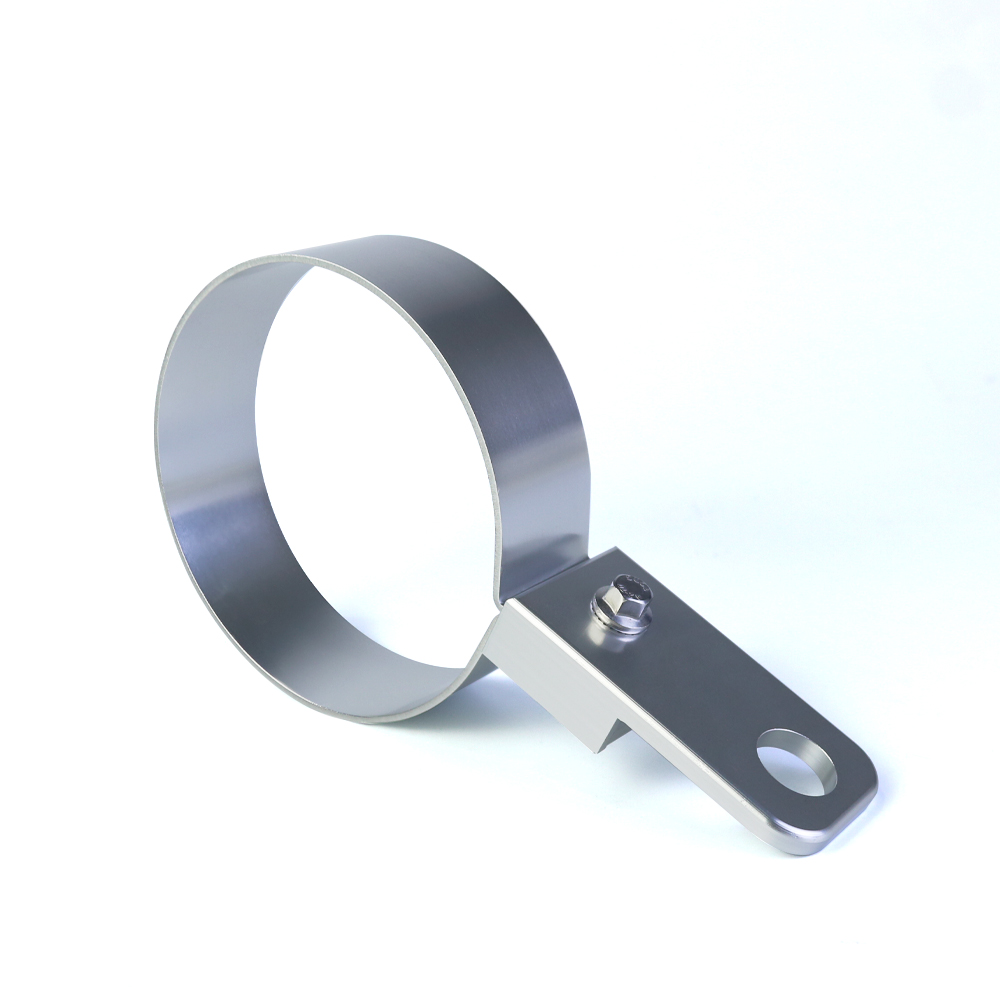

Kakaretso ea Sehlahisoa

Ha ho tluoa tabeng ea ho etsa likarolo tsa tšepe, ho nepahala le boleng ke tsa bohlokoa. Hore na o lefapheng la likoloi, sefofane, lisebelisoa tsa elektroniki, kapa indasteri, ho ba le likarolo tse nepahetseng tse etselitsoeng lintlha tsa hau hantle ho ka ntlafatsa ts'ebetso ea sehlahisoa sa hau haholo. Ke moo lits'ebeletso tsa ho sila, ho seha, le ho bentša ho sebelisoang ka mokhoa o ikhethileng. Ts'ebetso ena e fana ka tharollo e felletseng ea ho hlahisa likarolo tsa boleng bo holimo, tse entsoeng ka nepo tse fihlelang litlhoko tse ikhethang tsa projeke ea hau.

Ke Lintho Life Tse Hlophisitsoeng Tse Etsang Metal Milling, Cutting, and polishing?

1.Metal Milling

Ho sila ke ts'ebetso ea machining e kenyelletsang ho sebelisa lithulusi tsa ho itšeha tse potolohang ho tlosa thepa ho tsoa ho workpiece. Sena se re lumella ho etsa likarolo tse nang le libopeho tse rarahaneng, litekanyo tse nepahetseng, le libaka tse boreleli. Ho sila ka tšepe ho bohlokoa bakeng sa ho hlahisa likarolo tse nang le meralo e ikhethang le litlhaloso, hore na o sebetsa ka tšepe, aluminium, koporo, koporo kapa litšepe tse ling.

• Precision milling e nepahetse bakeng sa ho hlahisa likere, li-brackets, housings, le likarolo tse ling tse hlokang maemo a phahameng a mamello.

2.Metal Cutting

Ho itšeha ke mokhoa o fapaneng o re lumellang ho bopa le ho boholo ba litšepe ho latela litlhaloso tsa hau hantle. Sena se ka finyelloa ka mekhoa e fapaneng, joalo ka ho itšeha ka laser, ho itšeha ka plasma, ho itšeha ka sefofane sa metsi le ho kuta. Ho itšetlehile ka litlhoko tsa thepa le moralo, re khetha mokhoa o sebetsang ka ho fetisisa oa ho itšeha ho finyella liphello tse hloekileng, tse nepahetseng.

• Ho itšeha ka tšepe ho etsa bonnete ba hore karolo ka 'ngoe e lumellana le moralo oa hau, ebang ke sehiloeng se bonolo kapa sebopeho se rarahaneng.

3.Ho bentša tšepe

Ho pholisa ke mokhoa oa ho qetela oa ho etsa likarolo tsa tšepe. Ts'ebeletso ena e bohlokoa bakeng sa ho ntlafatsa boipiletso ba karolo ha e ntse e ntlafatsa boleng ba eona. Ho bentša ho ka batalatsa libaka tse makukuno, ha tlosa li-burrs, 'me ha etsa hore metsoako ea tšepe e be e boreleli, e benyang.

•Polishe ea tšepe e ikhethileng e netefatsa hore likarolo tsa hau ha li sebetse hantle feela empa li boetse li na le chebahalo ea boleng bo holimo e hlokahalang bakeng sa lihlahisoa tse sebelisoang lits'ebetsong tse shebaneng le bareki, joalo ka lintho tse mabothobotho, likarolo tsa mekhabiso, le lisebelisoa tsa bongaka.

Ke Hobane'ng ha U Khetha ho Ntlafatsa Metal, ho Seha, le ho Polefatsa?

•Ho nepahala le ho Nepaha ho Phahameng

Motsoako oa mechine e tsoetseng pele le litsebi tsa litsebi li re lumella ho hlahisa likarolo tsa tšepe tse nang le mamello e thata haholo. Ebang ke ho sila kapa ho itšeha, lits'ebeletso tsa rona li netefatsa ho nepahala ho hoholo ka boholo, ho netefatsa hore likarolo tsa hau li kena hantle ka har'a kopano kapa mochini oa hau.

• Tailored Tharollo bakeng sa Litlhoko tse Ikhethang

Morero o mong le o mong o na le litlhoko tse ikhethang, 'me litšebeletso tsa rona tsa tšepe tse hlophisitsoeng li etselitsoe ho fihlela litlhoko tseo tse khethehileng. Hore na o rala likarolo tsa mochini o sebetsang hantle haholo, litsamaiso tse rarahaneng tsa mochini, kapa lihlahisoa tsa bareki tse majabajaba, re fana ka litharollo tse feto-fetohang, tse hlophisitsoeng. Ho tloha ho meralo e rarahaneng ho isa ho boholo ba tloaelo, re fana ka lits'ebeletso tse nepahetseng ho theha likarolo tse phethahetseng.

•Mekhoa e mengata ea ho sebetsa ka tšepe ka tlas'a marulelo a le mong

Ka ho fana ka ho sila, ho seha le ho bentša ka tlung, re nolofatsa ts'ebetso ea tlhahiso le ho fokotsa tlhoko ea ho rekoa. Sena ha se netefatse feela linako tsa phetoho e potlakileng empa hape se lumella taolo e kholo holim'a boleng boemong bo bong le bo bong ba tlhahiso. Hore na o etsa li-prototypes kapa li-run tse kholo, re na le bokhoni ba ho sebetsana le litlhoko tsohle tsa hau tsa ho sebetsa ka tšepe.

• Khetho ea Lintho Tse Ngata

Re sebetsa ka mefuta e mengata ea litšepe, ho kenyelletsa tšepe e sa hloekang, aluminium, koporo, koporo le titanium. Hore na o hloka likarolo tsa lits'ebetso tse matla haholo kapa likarolo tse hananang le kutu, re ka khetha lisebelisoa tse ntle ka ho fetisisa bakeng sa litlhoko tsa hau tse ikhethang.

•Ho Felisoa ha Boemo ba Boleng bo Phahameng

Ts'ebetso ea ho bentša ha e ntlafatse boleng bo botle ba likarolo tsa hau feela empa hape e ntlafatsa ho thibela kutu, ho boreleli le ho se mamelle. Re fana ka mekhoa e fapaneng ea ho bentša ho lumellana le qetello eo u e batlang, ho tloha ho liipone tsa seipone ho isa ho satin kapa matte finishes.

•Tlhahiso e Senyang Litšenyehelo

Litšebeletso tsa ho sila, ho itšeha le ho bentša ho ka ba le litšenyehelo tse ngata ho feta mekhoa ea khale ea tlhahiso, haholo-holo ha u batla tlhahiso ea boleng bo phahameng kapa likarolo tse tloaelehileng tse tloaelehileng. Re ntlafatsa ts'ebetso ea tlhahiso ho fokotsa litšila le ho fokotsa litšenyehelo ha re ntse re boloka maemo a holimo a boleng le ho nepahala.

Lits'ebetso tsa Bohlokoa tsa Ts'ebetso ea Ts'ebetso ea Ts'epe e Ikemetseng, ho Seha, le ho Polefatsa

•Likarolo tsa Likoloi

Ho tloha ho likarolo tsa enjene ho ea ho li-brackets le matlo a tloaelehileng, lits'ebeletso tsa ho roala tšepe le ho itšeha li bohlokoa ho hlahiseng likarolo tsa likoloi. Litšebeletso tsa rona li thusa ho hlahisa likarolo tsa koloi tsa boemo bo holimo tse lekanang hantle le ho sebetsa tlas'a maemo a boima. Re boetse re fana ka polishing bakeng sa likarolo tse hlokang qetello e boreleli bakeng sa mabaka a botle le a ts'ebetso, joalo ka malebela a ho ntša metsi kapa likotoana tsa mekhabiso ea mekhabiso.

•Sefofane le Sefofane

Indasteri ea sepakapaka e hloka likarolo tse bobebe le tse tšoarellang haholo. Re sebelisa ho sila, ho seha le ho bentša, re etsa likarolo tsa sepakapaka joaloka lisaka tsa sefofane, lisebelisoa tsa ho lisa, le likarolo tsa enjene tse nang le litekanyetso tse nepahetseng. Litšebeletso tsa rona tsa polishing li netefatsa hore likarolo tsa bohlokoa li boloka pheletso ea tsona e boreleli bakeng sa phallo ea moea e ntlafalitsoeng le khohlano e fokotsehileng.

•Likaroloana tsa Elektronike le Motlakase

Ho nepahala hoa hlokahala ha ho etsoa lisebelisoa tsa elektronike tse kang lihokelo, lisinki tsa mocheso, le matlo a boto ea potoloho. Ka ho sila le ho itšeha ka mokhoa o ikhethileng, re etsa likarolo tsa ho mamellana tse lumellanang hantle le lisebelisoa tsa hau. Mokhoa oa ho bentša o ntlafatsa boleng ba boleng le botle bo botle, haholo-holo lihlahisoa tse shebaneng le bareki.

•Lisebelisoa tsa bongaka le tsa meno

Liindasteri tsa bongaka le tsa meno li hloka likarolo tse lumellanang le biocompatible le tse nepahetseng haholo. Likarolo tsa tšepe tse sililoeng le tse sehiloeng li sebelisoa lisebelisoa tse kang li-implants, lisebelisoa tsa ho buoa le meqhaka ea meno. Litšebeletso tsa rona tsa ho bentša li thusa ho netefatsa hore likarolo tsena li boreleli, ha li na li-burrs, 'me li bolokehile bakeng sa tšebeliso ea bongaka.

• Thepa le Mechini ea Liindasteri

Ho tloha matlong a mechini ho isa ho likere le li-shafts, re fana ka ho sila, ho seha le ho bentša ka mokhoa o ikhethileng bakeng sa likarolo tse fapaneng tsa indasteri. Litšebeletso tsa rona li thusa ho hlahisa likarolo tse mamellang khatello e feteletseng le maemo a holimo a ho khathala ha li ntse li boloka ts'ebetso e phahameng.

• Lintho tse Khabisitsoeng Hantle le tsa Mabono

Bakeng sa lintho tse hlokang ho phethoa ha maemo a holimo, joalo ka lioache tse majabajaba, mabenyane, kapa lihlahisoa tsa bareki ba maemo a holimo, ho belisoa ha tšepe ho bohlokoa. Re fana ka lits'ebeletso tse ikhethileng ho fihlela pheletso e phethahetseng bakeng sa likarolo tsena, ho netefatsa hore li hlahella ka ponahalo e se nang sekoli, ea boleng bo holimo.

Haeba u batla lits'ebeletso tsa boleng bo holimo, tse ikamahanyang le ts'ebetso ea ho sila, ea ho seha le ea ho bentša, u se ke ua sheba hole. Re sebetsa ka thata ho fana ka likarolo tse entsoeng ka mokhoa o nepahetseng bakeng sa liindasteri tse fapaneng, ho netefatsa hore likarolo tsa hau li finyella litekanyetso tse phahameng ka ho fetisisa tsa ts'ebetso, ponahalo le ho tšoarella.

Q1: Ke Mefuta Efe ea Litšepe E ka sebetsoang ka ho Sebelisa Litšebeletso Tsee?

A1: Litšebeletso tsena li loketse mefuta e mengata ea litšepe, ho kenyelletsa: Aluminium Steel (ho kenyeletsoa tšepe e sa hloekang le carbon steel) Brass Copper Titanium Nickel Alloys Magnesium Precious Metals (khauta, silevera, joalo-joalo) Ho sa tsotellehe hore na u sebetsa ka litšepe tse bonolo tse kang aluminium kapa li-alloys tse thata joaloka titanium, ho sebetsana le litlhoko tse sa tšoaneng tsa ts'ebetso ea tšepe ho finyella litlhoko tsa hau tsa tšepe.

Q2: U Etsa'ng ho Etsa bonnete ba hore Boleng ba Litšebeletso tsa Metal tse Customized?

A2: Ho netefatsa liphetho tsa boleng bo holimo, mofani oa litšebeletso tsa setsebi ka tloaelo o latela mekhoa ena: Mechini e tsoetseng pele: Ho sebelisa mechine ea morao-rao ea ho sila ea CNC (Computer Numerical Control), li-laser cutters, le lisebelisoa tsa ho bentša bakeng sa ho nepahala le ho tsitsisa. Teko e Matla: Ho etsa licheke tsa taolo ea boleng nakong eohle ea ts'ebetso ea tlhahiso ho netefatsa mamello, boholo le liphetho. Litsebi tse nang le boiphihlelo: Litsebi tse nang le boiphihlelo li netefatsa hore karolo ka 'ngoe e kopana le litlhaloso tsa hau le litekanyetso tsa indasteri. Litlhahlobo tsa Material: Ho netefatsa hore tšepe e sebelisitsoeng ke ea boleng bo holimo, e nang le metsoako e loketseng ea alloy bakeng sa matla, ho hanyetsa kutu le ts'ebetso.

Q3: Mokhoa ona o nka nako e kae?

A3: Karolo e Ratang: Meralo e rarahaneng haholoanyane e tla nka nako e telele ho sila kapa ho seha. Bongata: Liodara tse kholo hangata li hloka nako e eketsehileng, empa tlhahiso ea batch e ka ntlafatsa katleho. Lisebelisoa: Litšepe tse ling li bonolo ho sebetsa ho feta tse ling, tse amang nako ea tlhahiso. Qetello: Ho etsa polishing ho ka eketsa nako ea ts'ebetso, ho latela boemo ba ho qetela bo hlokahalang. Ka kakaretso, nako e ka tloha matsatsing a 'maloa bakeng sa mesebetsi e bonolo ho ea libeke tse' maloa bakeng sa litaelo tse kholo, tse rarahaneng, kapa tse nepahetseng haholo.

Q4: Na U ka Sebelisa Litaelo le Li-Prototypes Tse Tloaelehileng?

A4: E, lits'ebeletso tsa tšepe tse ikhethileng li loketse tlhahiso ea li-batch tse nyane le prototyping. Hore na o hloka li-prototype tsa hang-hang kapa o itokisetsa tlhahiso ea bongata, lits'ebeletso tsena li ka amohela litlhoko tsa hau tse ikhethileng. Ho sebetsa haufi-ufi le moetsi ho netefatsa hore li-prototype tsa hau li fihlela litebello tsa moralo mme li se li loketse ho hlahlojoa le ho ntlafatsoa.

Q5: Na U ka sebetsana le Mabelo a Maholo a Tlhahiso?

A5: E, lits'ebeletso tsa tšepe tse ikhethileng li ka sebetsana le merero e menyenyane ea tloaelo le tlhahiso e kholo ea tlhahiso. Haeba u rera tlhahiso ea bongata, mofani oa litšebeletso ea nang le litsebo o tla ntlafatsa ts'ebetso ea tlhahiso bakeng sa katleho ha a ntse a boloka boleng le ho nepahala.