Likarolo tsa Lifofane tsa Struts

Tsoelo-pele ho Theknoloji ea Mechini ea CNC e Fetola Tlhahiso ea Likarolo tsa Strut tsa Lifofane

Lefatšeng le rarahaneng la boenjiniere ba lifofane, ho nepahala le ho tšepahala ke tsona tse ka sehloohong. Li-struts tsa lifofane ke likarolo tsa bohlokoa tse tšehetsang boima ba sefofane nakong ea ho fihla le ho sebetsa fatše, 'me li hloka litekanyetso tse phahameng ka ho fetisisa tsa tlhahiso. Ha thekenoloji e ntse e tsoela pele, machining a tsamaiso ea linomoro tsa khomphutha (CNC) e fetohile phetoho ea ho hlahisa likarolo tsena tsa bohlokoa. Sengoliloeng sena se hlahloba kamoo machining a CNC a fetotseng phetoho ea ho etsoa ha likarolo tsa sefofane, ho ntlafatsa ts'ebetso ea sefofane, polokeho le ts'ebetso e ntle.

Karolo ea CNC Machining ho Aerospace:

CNC machining haesale e le karolo ea bohlokoa ea tlhahiso ea lifofane, e fana ka ho nepahala ho ke keng ha bapisoa le ho pheta-pheta. Tlhahisong ea likarolo tsa strut ea sefofane, mamello e tiileng le li-geometri tse rarahaneng ke ntho e tloaelehileng, 'me machining a CNC a tiisa botsitso le boleng boemong bo bong le bo bong ba tlhahiso. Ka ho fetolela meralo ea dijithale hore e be likarolo tsa 'mele ka nepo e fetelletseng, metjhini ea CNC e thusa lienjiniere tsa sefofane ho etsa li-struts tse fihlelang litekanyetso tse thata tsa polokeho le ts'ebetso.

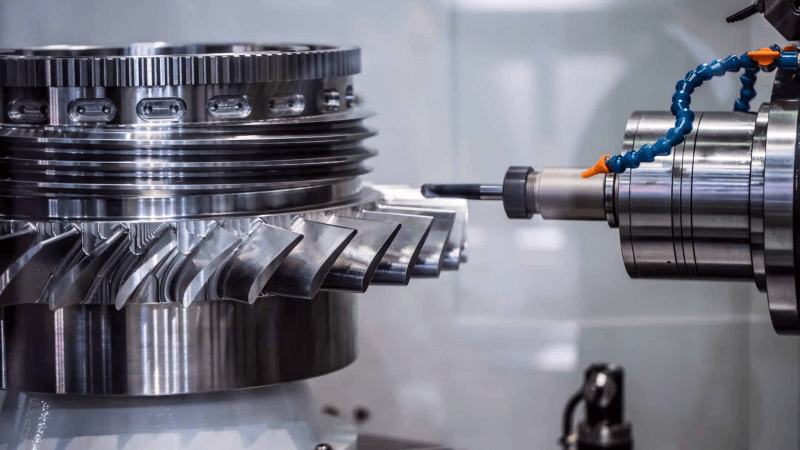

Precision Engineering:

Likarolo tsa sepakapaka sa lifofane, joalo ka liboka tsa lisebelisoa tsa ho lulisa le li-cylinders tsa hydraulic, li hloka mochini o rarahaneng ho fihlela lintlha tse hlokahalang. CNC machining e ipabola sebakeng sena, ho etsa ka nepo le ho qeta li-alloys tsa tšepe tse sebelisoang hangata lits'ebetsong tsa sefofane. Ho sa tsotellehe hore na ho sila, ho reteleha kapa ho sila, mechine ea CNC e fana ka ho nepahala ha sub-micron, ho netefatsa hore karolo ka 'ngoe e finyella litlhoko tse nepahetseng tsa moralo.

Li-geometri tse rarahaneng:

Li-struts tsa sejoale-joale tsa lifofane li etselitsoe ho mamella matla a maholo ha li ntse li fokotsa boima ba 'mele le ho ntlafatsa boleng ba sebopeho. Hangata sena se hloka likarolo tsa tlhahiso tse nang le li-geometri tse rarahaneng, joalo ka libaka tse kobehileng, li-profiles tse tapered le li-cavities tse ka hare. Bokhoni ba machining ba CNC, ho kenyeletsoa machining a li-multi-axis le lisebelisoa tse tsoetseng pele tsa lisebelisoa, li thusa bahlahisi ho hlahisa likarolo tsena tse rarahaneng habonolo. Ka ho sebelisa matla a software ea CAD/CAM, baenjiniere ba ka ntlafatsa meralo bakeng sa ts'ebetso e ntlafalitsoeng ea tlhahiso le ho tsamaisa mekhoa ea tlhahiso.

Material Flexibility:

Lisebelisoa tsa strut tsa lifofane hangata li entsoe ka thepa e matla e phahameng joalo ka aluminium, titanium le tšepe e sa hloekang ho mamella maemo a thata a sefofane. CNC machining e fana ka mefuta-futa e ke keng ea lekanngoa ha ho etsoa li-alloys tsena, ho lumella ho itšeha hantle, ho cheka le ho theha ntle le ho senya thepa ea thepa. Ebang ke bulkhead, trunnion kapa piston rod, mechine ea CNC e khona ho sebetsana le mefuta e mengata ea lisebelisoa habonolo, ho netefatsa hore karolo ka 'ngoe e finyella litekanyetso tse thata tsa indasteri ea lifofane.

Netefaletso ea boleng:

Tlhahisong ea sepakapaka, taolo ea boleng ha e buisane. Ho tšepahala le polokeho ea lifofane ho itšetlehile ka botšepehi ba karolo e 'ngoe le e' ngoe, ho kenyelletsa le likarolo tsa strut. Mechine ea CNC e bapala karolo ea bohlokoa ho netefatsa netefatso ea boleng ka ho etsa hore ho behoe leihlo ka nako ea 'nete le tlhahlobo ea likarolo tse entsoeng ka mochini. Ka lisebelisoa tse tsoetseng pele tsa metrology tse kenyellelitsoeng lits'ebetsong tsa CNC, bahlahisi ba ka netefatsa ho nepahala ha boholo, pheletso ea bokaholimo, le bots'epehi ba thepa nakong eohle ea ts'ebetso ea tlhahiso, ba fokotsa kotsi ea bofokoli le ho netefatsa ho lateloa ha melao ea tsamaiso.

Sebetsa le Katleho ea Litšenyehelo:

Ha o ntse o boloka litekanyetso tsa boleng bo sa thekeseleng, mochini oa CNC o boetse o fana ka melemo e mengata mabapi le ts'ebetso le katleho ea litšenyehelo. Ka ho iketsetsa mesebetsi e pheta-phetoang le ho ntlafatsa maemo a machining, bahlahisi ba ka nolofatsa tlhahiso ea mosebetsi le ho fokotsa linako tsa ho etella pele. Holim'a moo, scalability ea CNC machining e lumella tlhahiso e ntle ea lihlopha tse nyane le tse kholo tsa likarolo tsa sefofane, ho fana ka maemo a bonolo ho fihlela litlhoko tse matla tsa indasteri ea sefofane. Ha nako e ntse e ea, sena se bolela litšenyehelo tse tlase tsa tlhahiso le tlholisano e ntlafetseng bakeng sa baetsi ba lifofane.

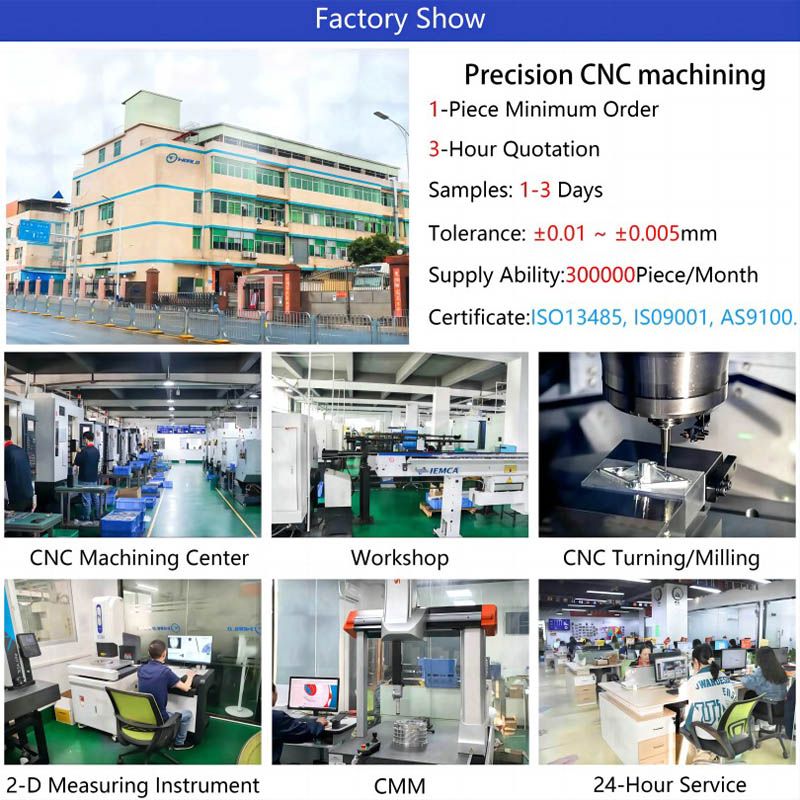

P: Khoebo ea hau ke efe?

A: Tšebeletso ea OEM. Sebaka sa rona sa khoebo ke CNC lathe e sebetsitsoeng, ho phethoha, ho hatakela, joalo-joalo.

Q.U ka ikopanya le rona joang?

A: U ka romella lipotso tsa lihlahisoa tsa rona, li tla arajoa nakong ea lihora tse 6; 'me u ka ikopanya le rona ka tsela e sa tobang ka TM kapa WhatsApp, Skype kamoo u ratang.

P. Ke tlhahisoleseding efe eo ke lokelang ho o fa yona bakeng sa ho botsisisa?

A: Haeba u na le litšoantšo kapa lisampole, pls ikutloe u lokolohile ho re romella, 'me u re bolelle litlhoko tsa hau tse khethehileng tse kang thepa, mamello, phekolo ea holim'a metsi le chelete eo ue hlokang, joalo-joalo.

Q. Ho thoe'ng ka letsatsi la ho pepa?

A: Letsatsi la ho fana ke matsatsi a ka bang 10-15 ka mor'a ho fumana tefo.

Q. Ho thoe'ng ka lipehelo tsa tefo?

A: Ka kakaretso EXW KAPA FOB Shenzhen 100% T / T esale pele, 'me re ka boela ra buisana accroding ho tlhokahalo ea hao.