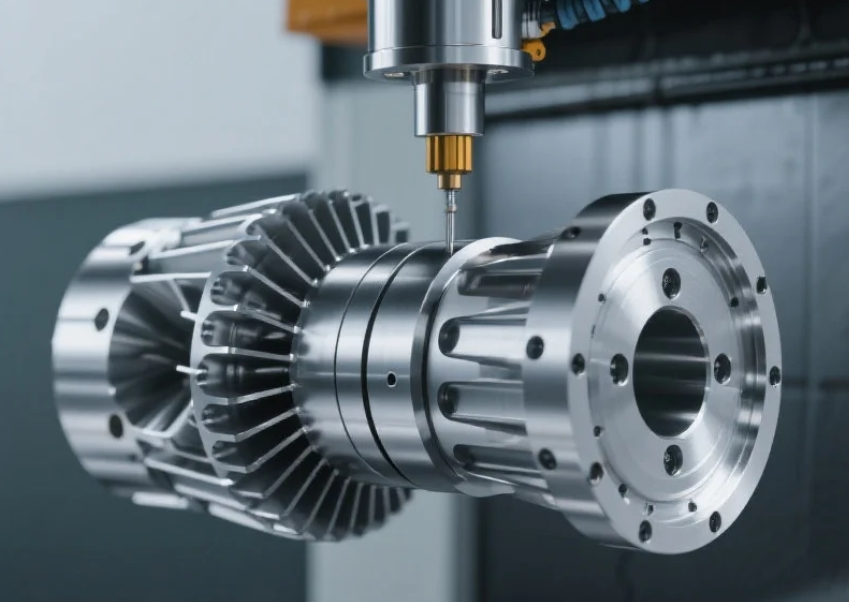

Aerospace Thin-Wall Structural Parts Precision Machining

Lefapheng la lifofane, ho nepahala ha se tlhokahalo feela—ke mokhoa oa bophelo. Likarolo tsa sebopeho sa lebota le tšesaane, joalo ka liphanele tsa fuselage, likhopo tsa mapheo, le likarolo tsa enjine, li hloka boitseanape ba mochini o lekanyang ho nepahala ho hoholo le bots'epehi ba sebopeho. Joalo ka moetsi ea etelletseng pele ea sebetsanang le ho sebetsa ka mokhoa o nepahetseng oa likarolo tsa sepakapaka tse tšesaane tsa mabota, re kopanya theknoloji e tsoetseng pele, taolo e matla ea boleng, le boiphihlelo ba lilemo tse mashome ho fana ka likarolo tse fihlelang litekanyetso tse phahameng ka ho fetisisa tsa lefats'e.

Ke Hobane'ng ha U Re Khetha? Theknoloji e Tsoetseng Pele e Kopana le Tsebo

Thepa ea 1.State-of-the-Art: Setsi sa rona se na le mechini ea 5-axis CNC, litsamaiso tsa ho sila ka lebelo le phahameng (HSM), le lisebelisoa tsa laser-ultrasonic hybrid processing, tse re nolofalletsang ho sebetsana le li-geometri tse rarahaneng le marako a masesaane haholo (a tšesaane joalo ka 0.5mm) a nang le deformation e fokolang. Mohlala, theknoloji ea rona ea HSM e fihlella lebelo la spindle le fetang 15,000 RPM, e fokotsa nako ea machining ka 40% ha e ntse e ntlafatsa boleng ba ho qetela.

2.Proven Machining Solutions: Likarolo tsa aerospace tse tšesaane li atisa ho sisinyeha le ho senyeha ha li ntse li sebetsa. Ka tlhahlobo ea finite element (FEA) le maano a machining a feto-fetohang, re ntlafatsa maemo a ho itšeha (mohlala, sekhahla sa phepelo, botebo ba sehiloeng) ho fokotsa mathata ana. Mokhoa oa rona oa "match o feto-fetohang" oa "multi-flexible", o khothalelitsoeng ke baetapele ba indasteri joalo ka AVIC XAC, o netefatsa ho nepahala ha boholo ka har'a ± 0.02mm.

3.Qetellong-to-Qetellong Tiisetso ea Boleng: Karolo e ngoe le e ngoe e etsa tlhahlobo ea mekhahlelo e meraro:

● Ho shebella ka nako ea sebele ho sebelisa laser scanning bakeng sa taolo ea deformation ea in-process.

● Tiiso ea CMM (Coordinate Measuring Machine) bakeng sa mamello e boima.

● Teko ea botšepehi ba holim'a metsi ho finyella litekanyetso tsa ho hanyetsa mokhathala oa boemo ba sefofane .

Likopo: Moo ho Nepahetseng ho Bohlokoa Haholo

Litšebeletso tsa rona tsa mochini li fana ka:

● Likarolo Tsa Sebopeho sa Sefofane: Likhopo tsa mapheo, li-bulkheads, le liphanele tsa fuselage tse entsoeng ka 7075-T6 aluminium le li-alloys tsa Ti-6Al-4V tsa titanium, tse lokiselitsoeng ho lekana matla le boima ba 'mele .

● Likarolo tsa Enjene: Li-blade tsa turbine le lik'hasete tse hlokang mochini o sa cheseheng oa Inconel 718 .

● Litsamaiso tsa Satellite & Tšireletso: Li-brackets le lihokelo tsa Ultra-lightweight tse nang le mamello e thata.

Melemo e Eteletseng Pele ea Indasteri

● Tšebeliso ea Lintho: Finyella ho fihlela ho 95% ea katleho ea thepa ka litsela tse ntlafalitsoeng, ho fokotsa litšila le litšenyehelo.

● Prototyping e Potlakileng: Ho tloha ho moralo oa CAD ho ea ho likarolo tse phethiloeng ka lihora tse 72, tse tšehetsoeng ke lipapiso tsa machining tsa axis tsa sebele .

● Tšehetso e Feletseng: Litšebeletso tsa Post-machining li kenyelletsa anodizing, ho penta, le ho paka ka tloaelo ho netefatsa hore likarolo li fihla li se li loketse sefofaneng.

SEO-Optimized Content, Integrated Keywords

Ho ntlafatsa ponahalo ea mantsoe a kang "litšebeletso tsa machining tsa lebota le lesesaane la sefofane" le "mechine e nepahetseng ea CNC bakeng sa sefofane," sengoloa sena:

●E sebelisa mantsoe a bohlokoa a LSI (mohlala, “high-speed milling,” “low-deformation machining”) ntle le ho tlatsa lintho tse ngata haholo .

● E tsamaellana le litataiso tsa EAT tsa Google ka ho supa maemo a tekheniki (mohlala, ISO 9001, AS9100) le lithuto tsa liketsahalo .

●E kenyelletsa litšoantšo tse ntlafalitsoeng (mohlala, “HSM-machine-aerospace-parts.jpg”) bakeng sa ho khasa hantle.

Molekane oa Hao ho Aerospace Innovation

Ka sehlopha sa litšebeletso tsa bareki sa 24/7 le tiisetso ea lilemo tse 15 ho likarolo tsa bohlokoa, re ikemiselitse ho sebelisana nako e telele. Lekola li-portfolio tsa rona tsa merero e 500+ e tsamaisitsoeng ka katleho bakeng sa bareki ba kang COMAC le Lockheed Martin.

Ikopanye le rona kajeno ho buisana ka morero oa hau - hobane ts'ebetsong ea mochini oa sefofane, ha ho sebaka sa ho inehela.

P: Khoebo ea hau ke efe?

A: Tšebeletso ea OEM. Sebaka sa rona sa khoebo ke CNC lathe e sebetsitsoeng, ho phethoha, ho hatakela, joalo-joalo.

Q.U ka ikopanya le rona joang?

A: U ka romella lipotso tsa lihlahisoa tsa rona, li tla arajoa nakong ea lihora tse 6; 'me u ka ikopanya le rona ka tsela e sa tobang ka TM kapa WhatsApp, Skype kamoo u ratang.

P. Ke tlhahisoleseding efe eo ke lokelang ho o fa yona bakeng sa ho botsisisa?

A: Haeba u na le litšoantšo kapa lisampole, pls ikutloe u lokolohile ho re romella, 'me u re bolelle litlhoko tsa hau tse khethehileng tse kang thepa, mamello, phekolo ea holim'a metsi le chelete eo ue hlokang, joalo-joalo.

Q. Ho thoe'ng ka letsatsi la ho pepa?

A: Letsatsi la ho fana ke matsatsi a ka bang 10-15 ka mor'a ho fumana tefo.

Q. Ho thoe'ng ka lipehelo tsa tefo?

A: Ka kakaretso EXW KAPA FOB Shenzhen 100% T / T esale pele, 'me re ka boela ra buisana accroding ho tlhokahalo ea hao.